Hello everyone,

Summer isn’t slowing down the activity at the Wayne College Makerspace. All three of our printers are being put to good use. Thanks to the Romich Foundation, we also recently purchased finishing equipment such as a Dremel tool for cutting/shaping/polishing, some table clamps, and a lighted magnifier. Although 3D printing is dainty when it comes to plastic consumption, we print so much that we need to buy more spools sooner than we thought.

A student who works for The Wilburt Company wanted to mount a webcam inside a piece of large equipment, so he designed the mount in CAD and brought it to Wayne for printing. The webcam mount came-out perfectly and is now being used as intended. Good job on the design, Andrew! The webcam mount is the white object below:

Dusty is hard at-work with the RC car that will be totally 3D printed. He is currently working on the suspension system. The yellow parts are printed with PLA plastic (more rigid) while the red parts are printed in ABS which allows some flexing. It will be exciting to see the car as it is being built:

Our own Chris from Technical Support Services is learning CAD and 3D printing. His current project is designing an RC airplane from foam board. He designed the engine mount and rudder actuators in CAD then printed them on the 3D printer. The plane flies beautifully (until Chris crashed it into the Wayne soccer goal cage).

Dean Deckler’s coffee mug cap is coming along well. Dusty designed a perfectly fitting replacement in CAD. He printed the cap with ABS plastic so that it can withstand the heat of hot coffee. However, 3D printing is a rough process, allowing for bacteria to form. This makes 3D printed objects not safe for food use. Dusty smoothed the cap with acetone vapor, solving some of this problem. However, the process shrunk the cap slightly, so a larger version needs printed:

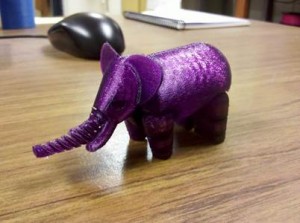

And last but not least, we printed an elephant! Not a large one, but this little guy that printed laying down, but the legs are jointed and start working as soon as its removed from the printer. Our elephant can walk!

Read this heart warming story about a boy born without fingers on one hand, a mechanical hand invented by a South African carpenter, and a 17-year old who 3D printed this hand from Thingiverse.com:

Read this heart warming story about a boy born without fingers on one hand, a mechanical hand invented by a South African carpenter, and a 17-year old who 3D printed this hand from Thingiverse.com:

http://americanprofile.com/articles/give-him-a-hand

Until our next installment…

Tom