Hello everyone,

It has certainly been a busy past couple of weeks! We offered our first workshop in the new 3D Lab, composed of four days and 16 hours of training on CAD design, 3D printing, 3D scanning, building a makerspace, and more. We hosted around 10 Northwestern Schools faculty & staff, community members, and a student or two. Thanks to Dusty’s excellent lessons, the attendees really enjoyed the experience and will soon teach the concepts to their own students. Thanks, Debbie, for taking photos!

We hope to visit the Orrville Boys and Girls Club soon to offer lessons to their kids on CAD designing, 3D printing, and 3D scanning. More news coming.

Our portable printer used for offsite demonstration (affectionately named “Polly”) experienced a problem a couple of weeks ago. The print platform would not heat to 100 degrees Celsius, which is necessary for prints to stick to the platform. Thankfully the printer has a one-year warranty, so a replacement heating element was mailed to us ASAP. Always ready for a challenge, Dusty had it quickly installed.

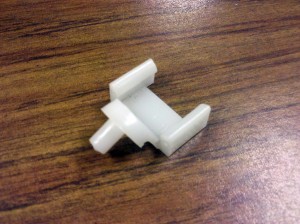

In the design department, Paul from the Daily Record brought a window clip that frequently breaks due to a weak design. Dusty redesigned it with AutoDesk Inventor, but discovered that the dimensions were distorted when placed in the 3D printing software. So he designed it again with Solidworks. Not overly pleased with the printed clips from the Makerbox, we plan to print the clips with Polly soon.

Dusty also invented a clip for hanging items from the top of a door. This was a special design because he taught his mother how to create it in CAD! The clip works wonderfully and his mother is quite pleased.

We have a number of projects to complete with only one week before the start of classes. It will be an exciting semester as engineering classes use the 3D printer technology for their various projects. Stay tuned!

Thanks to a new company named 3D Babies, you can a fetus scanned and printed using 3D ultrasound images! I am not kidding. What a way to enjoy your tiny wonder for years to come:

https://www.asme.org/engineering-topics/articles/manufacturing-processing/3d-delivery

In the world of prothetics, a 17-year-old creates a 3D printed arm using $250 of materials. He made this for a fellow science fair attendee who would soon outgrow his/her $80,000 prosthetic:

http://inhabitat.com/17-year-old-creates-a-3d-printed-robotic-prosthetic-arm-for-250

Enjoy the rest of summer!

Tom