Hello everyone,

The engineering students are using the Wayne makerspace practically full-time, thankfully all three printers are basically working well. Students are designing motor parts for their current projects, some will be hand operated while others will be powered by air pressure. Their CAD designs are amazing.

We are always up for a challenge to create and fix things, too. One of the tutors in the Learning Center owns a “string trimmer” that is basically a weed eater in a lawn mower form factor. The company went out of business, so he could not obtain replacement trimmer line. After bringing a sample to the makerspace, we printed replacement line with ABS plastic. If it works in his trimmer, we can experiment with printing with nylon for better durability:

Dusty also designed a plastic bearing for a proof-of-concept. The bearing printed as one piece in our large ABS printer, which works quite well as far as bearings go:

Last month, a large group from the American Society of Mechanical Engineers visited the makerspace for a talk and demonstration of 3D printing as it pertains to engineering. Dusty gave an excellent presentation on the subject. Some members requested CAD training which Dusty was more than happy to provide.

Nathan, one of our many enterprising students, desired a way to smooth the “layers” made by 3D printing. Exposing the object to acetone vapor is one solution, but it risks part deformation from prolonged exposure. He printed a cylindrical object, then shaved the outer skin with a lathe at home. The result was a perfectly smooth surface, devoid of layers!

This past weekend witnessed the Akron Mini Maker Faire event, in its second year in that city. Attendance doubled from last year, with 40 tables of exhibitionists and over 1,550 attendees. It was an exciting time. Dusty, Anthony, myself, and a Wayne student or two attended.

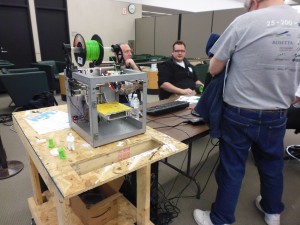

Second generation Makerbot

This 3D printer extrudes aluminum!

Spider robot

Spiderbot controlled by arm muscles

Robot course for kids FIRST LEGO League

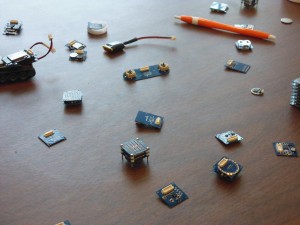

Tiny Arduino microcontrollers

Tom’s computerized Christmas lights

Explaining lights to lots of folks

A homemade “game controller” made of wood

An important hallmark in the growth of our makerspace, Northwestern Schools hosted a recognition ceremony for organizations who contributed to their success and growth of their new makerspace (named Imagination Station). Wayne College was the recipient of an award for offering advice on the creation of their space as well as offering a 16-hour CAD training and 3D printing workshop to their faculty & staff (courtesy of Dusty). It is quite an honor and we look forward to more collaboration with them in the future.

And last but not least, Dusty discovered that since the print heads on our 3D printers reach almost 450 degrees, it could make for an excellent way to pierce ears for earrings. Before we try this on students, he decided to test the theory on himself:

Dusty will report his findings after he returns from the Emergency Room.

See how 3D printing creates knee replacements that are customized for each patient, reducing complications and pain from join instability:

http://www.gizmag.com/3d-printing-custom-knee-replacement-conformis/34322/

SpaceX creates rockets and space transport vehicles, similar to (and assisting) NASA. See how they used 3D printing to create the SuperDraco thruster:

http://www.gizmag.com/superdraco-test/32292/