Hello everyone,

This has certainly been the week for the UAWC³ Lab connecting with community. We welcome businesses, schools, and community members to the lab for free tours and CAD lessons. And boy, have they come!

Dusty is into his fourth week of CAD lessons for representatives of Cerco, a leader in industrial ceramic solutions. About 4-5 employees are taught advanced concepts in AutoCAD 2015. Yesterday, Dusty taught them how to create a plastic water bottle, complete with threaded cap. We are thankful that we can offer services to this company.

Earlier yesterday afternoon, four students from Kingsway Christian School arrived for an introduction to CAD design and 3D printing. They have an interesting project, designing a replacement door pin that breaks frequently. Our own Nathan did an excellent job teaching the basics; we plan to visit the school to analyze the door to design a more rugged pin. It is an excellent example of Wayne College engineering students collaborating with students from other schools. We look forward to see how this project progresses.

Also yesterday, Morgan received representatives from United Disability Services to teach CAD design to one of their clients. They had a wonderful time learning the subject and interacting with Wayne College students. Way to go, Morgan!

Last week, the Holmes Center offered their annual Open House event. And the highlight of the event was (you guessed it) 3D printing! I had a wonderful time explaining the technology and engineering career possibilities with visitors that evening.

While the Open house event normally runs for two hours, we had to leave early as the nearby Pepto Bismol plant experienced an accidental explosion that caused their product to flood through buildings of the surrounding neighborhood.

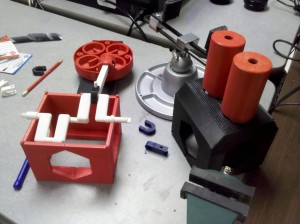

Back on the home front, students in the Tools for Engineering class put final touches on their 3D printed engines due this week. Four teams each designed a motor. The results are amazing and mesmerizing when in operation.

Our engineers are quite inventive. Here is Nathan converting a drill to a drum sander to smooth a motor part using an ordinary pencil!

Tami Mosser from The Bargain Hunter hosted an excellent interview with Dean Dan Deckler, Dusty Ball, and myself on the creation, growth, and success of the 3D Lab. We are honored when the community takes notice of our efforts, providing networking opportunities for continued growth and providing useful services. You can read the full article here:

http://www.holmesbargainhunter.com/article/20141117/EDUCATION/711179981/0/hbh?sectioncat=hbh

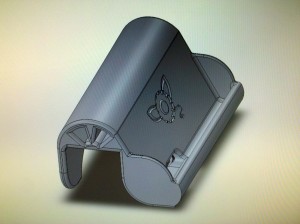

Josh, one of our aspiring students, started with zero CAD experience last Spring to now being an expert designer. Recently he created a cradle for his Nintendo Gameboy that allows it to be conveniently mounted to furniture.

In sad news, our portable printer was accidentally damaged while trying to fix a jammed extruder. With 3D printers, plastic particles sometimes do not melt in the heated nozzle, obstructing the flow of filament through the nozzle. In this case, the nozzle was too tight when we carefully tried to unscrew it, bending the shaft that it is attached to.

Polly will be out of commission until we can obtain a replacement nozzle heater assembly, hopefully soon!

See how a 3D printer can be modified to print flexible printed circuit boards (PCB’s) in the story below. The idea uses Ninjaflex Thermoplastic Elastomer (TPE) filament – it sticks to bare copper!

http://hackaday.com/2014/10/28/make-flexible-pcbs-with-your-3d-printer/

There won’t be a UAWC³ blog entry during the week of Thanksgiving, but we will resume posting the following week.

Tom