Hello everyone,

It’s hard to believe that a year has passed since the college received its first 3D printer. Thanks to the generosity of the dean and the community, we now have a dedicated room, three printers, and other “makerspace” equipment that fosters creativity and invention. The birth of this space has fostered the growth of the R/C Airplane Club, given engineering students a place to work and collaborate, the ability offer training to schools, companies, and community organizations, and is now an official stop during student orientation! We’ve come a long way in such a short time.

Last weekend, students Chris and Kenny to traveled to the MAPS Air Museum in Canton. Their goal was to scan the nosecone of a jet fighter using the 3D scanner provided by the Orrville Boys and Girls Club. Due to inclement weather that day, the museum was officially closed. But since Chris reserved the visit, they received a personal tour of the facility and complete access to the jet and hangar staff!

The nosecone on this plane was damaged; our students’ goal is to reconstruct a replacement with 3D printing. Here is the jet without its nosecone:

Chris made an amazing time-lapse video of the process; check out the 3D scanning that happens at 1:07:

With our students and 3D scanner safely back at Wayne College, they began work of re-creating the nose cone in software, using multiple images from the scanner:

Stay tuned as work on this impressive project continues.

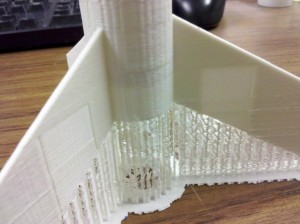

Engineering students in the Dynamics class are gearing up for the model rocket portion of the class. In addition to designing and fabricating the rockets, students are expected to calculate flight worthiness of their designs, such as wind tunnel tests, center of pressure calculations, center of balance studies, and more. One student has already begun 3D printing his rocket, including a custom designing locking mechanism to attach large fins together.

Earlier this semester, Senior Lecturer Betty Rogge graciously offered to create an introductory video of the 3D Lab. Morgan wrote a wonderful script, Dusty was the star, and Betty shot the video. After a lot of takes and editing, the resultant video is excellent (and quite humorous)! We hope to also create instructional videos on the use and maintenance of the 3D printers and other equipment. Thanks, Betty, for all of your hard work on this video!

Cars created with or enhanced by 3D printing are all the rage. German electric vehicle manufacturer StreetScooter recently completed the prototype of its C16, most of the exterior components of which were created using a Stratasys Objet1000 3D Production System:

http://www.gizmag.com/stratasys-3d-printed-streetscooter-c16/34845/

Think that 3D printed objects are unappealing? Think again. See how a replica of a vintage 1965 Shelby Cobra sportscar was created by the Oak Ridge National Laboratory (ORNL) for the 2015 North American International Auto Show (NAIAS) in Detroit:

http://www.gizmag.com/3d-printed-shelby-cobra-ornl/35575/

We have some big announcements to make in the coming weeks, so stayed tuned to the excitement in the 3D Lab!

Tom