Hello everyone,

The 3D Lab is a continual flurry of activity. On most days, all three printers are running simultaneously for student, staff, and personal projects. The printers are working fairly well, though our first printer was having quality issues. We have service plans for two of the printers, which is a wise investment to keep the machines functional during heavy use. Nathan noticed that the x-axis belt was loose and could not be tightened, so he installed a replacement belt free of charge from Makerbot. We received so many parts that it more than pays for the service plan’s annual fee.

We are also experimenting with “generic” filament brands as the Makerbot filament spools are quite expensive. The generic filament is half to two-thirds the cost. It generally works OK, though sometimes we need to adjust the extruder printing temperature for the various brands we are trying. If the temperature is too hot, the filament is runny and drips over the part. If it’s too cold, the filament jams inside the extruder.

Speaking of 3D printing, Cerco Corporation (a ceramics company in Shreve) reports more success stories after they received CAD training from Dusty in the 3D Lab last semester. A few weeks ago, they designed a rubber stamp to serialize their product. Recently, employees Eileen and Tammy designed and made a radius gauge for use on their production floor.

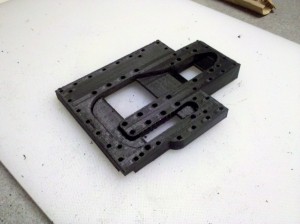

One of our students is using CAD and 3D printing to create an interesting personal project, a motherboard bracket for a liquid cooling system that he is inventing. The bracket includes holes to allow copper tubing to pass around various parts of the CPU and motherboard. This allows cooling that is quieter and more efficient than traditional fan based cooling. We are interested to the see results of this endeavor!

Betty Rogge, Senior Lecturer at Wayne College, created a wonderful introductory video of the 3D Lab. If you haven’t seen it yet, please click here. She offered to create instructional videos for the various equipment in our 3D Lab, ensuring that our students use them safely and efficiently. As before, Morgan will write the scripts and she and Dusty will star in the videos. Stay tuned to see them in the coming months!

The installation of the laser engraver is progressing. The maintenance department decided upon the installation location, the wall to be used for the exhaust port, and the source of an air compressor feed. Until the machine is operational, Barry Romich welcomed Dusty, Jennifer, and I to use his personal laser engravers for various projects. He jumped right in and worked alongside us, too!

Jennifer is throwing a bachelorette party and wanted to personalize wine glasses for each guest. Dusty and Barry figured out how to adapt his engraver to work with curved surfaces, something Barry had not tried before. The results were beautiful! The trick was to focus the laser’s beam in the middle of the wine glasses thickest and thinnest areas. That way it could engrave at each extreme without losing much focus.

There are a million projects going on in the 3D Lab; next week we’ll give you a glimpse of more of them!

Read a heart warming story as a University of Central Florida student creates a 3D printed arm prosthetic for a 7-year-old boy, personally delivered by Robert Downey, Jr. (Iron Man) himself!

http://hothardware.com/news/tony-stark-delivers-3d-printed-bionic-arm-to-7-year-old-iron-man-fan

Did you know that 3D printers can create objects at the molecular level? See how University of Illinois chemist Martin Burke created a machine that can systematically synthesize thousands of different molecules from a handful of starting chemicals.

Stay tuned for next week’s developments in the 3D Lab!

Tom