Hello everyone,

As the 3D Lab grows beyond its first year, we are polishing the initiative’s rough edges by establishing policies, maintenance and operations schedules, and documentation. In addition to the wonderful introductory video made by Betty Rogge, Morgan Silvey, and Dusty Ball, tutorial videos are being produced that demonstrate how to use the 3D Lab equipment. This is no small undertaking as video shooting and editing is intensive work. Many thanks to our video team for doing this.

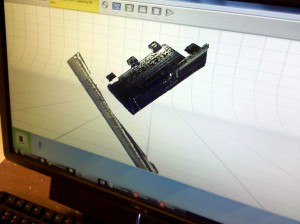

We now have easy-to-follow PDF instructions for our equipment, written specifically from our experiences in the 3D Lab. The instructions even have pictures! You are welcome to use our equipment after reading these documents; please stop by with any project that you have in-mind. We are also happy to teach equipment use in-person.

Ifrah is working with our Professor of History to create a vinyl-cut logo for his travel club. This logo will be used for shirts, cut from a special vinyl that works with our heat press. Ifrah used vector-art software to trace an outline from a bitmap logo that Paul provided via flash drive. As vector-art, the logo can be resized without loss in sharpness, the outline of which can followed by the vinyl cutter’s blade. The result is quite professional! Ifrah will soon press the design onto a shirt that Paul provided.

If you haven’t heard of www.thingiverse.com, be sure to explore this incredible website! Thingiverse is a repository of 3D printed designs and inventions of people of all ages from around the world. If you have an idea, upload your CAD design to be shared and enjoyed by others. It’s amazing what inventive things people dream-up, from useful household items to works of art.

Earlier this week, one of our students found a two-liter soda bottle dispenser on Thingiverse. The design involves propping the bottle upside down with a plunger system that releases the beverage into a cup from below. It’s an ingenious design. One thing needed is a rubber gasket to seal the bottle’s spout. We may soon receive a 3D printer that allows printing of rubber objects, so stay tuned as we pursue this project.

Another student, Caleb, wanted to 3D print a replacement battery cover for his game controller. Not finding a suitable replacement on Thingiverse and with no CAD skills to design a cover from scratch, Caleb used the 3D scanner. Our own Chris from Technical Support Services had plenty of 3D scanning experience from the jet fighter nosecone project, so he taught Caleb how to scan. The battery cover scanned perfectly into the computer in three dimensions and printed well, too. The resultant cover snaps into his game controller with a good fit!

Stay tuned next week as our engineering students begin 3D printing their model rockets in earnest as we draw near the end of semester.

Did you know that Amazon offers custom 3D printed objects that are mailed to your door? To speed delivery, the e-commerce giant is considering a fleet of “mobile manufacturing hubs” where 3D design files are printed inside delivery trucks then quickly delivered.

http://3dprint.com/46934/amazon-3d-printing-patent/

3D printing companies are coming to a city near you! 3D Systems (a large-scale 3D printer company) recently opened a filament manufacturing plant in Barberton, Ohio:

http://3dprint.com/11912/3d-systems-filament-materials/

Until next week,

Tom