Hello everyone,

The fifth week of the semester draws to a close. Engineering students built robots for a ball tossing competition, so the lab was full of moving parts and whirring motors. Their next assigning is to build robots that will seek and capture colored objects in a defined area. But here in the 3D Lab, that is only half of the story. Students of various disciplines print pre-designed objects from Thingiverse, others learn how to use the laser engraver to create beautiful gifts, and community members spend time interacting with students and inventing things in CAD. It is wonderful to see the different activities going on in that room each day; the energy is contagious!

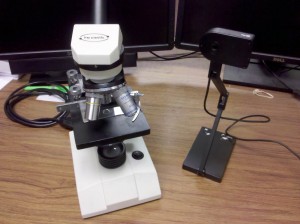

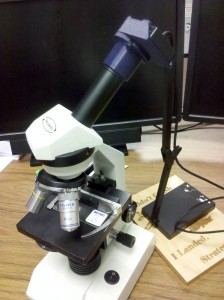

Over the past several weeks, a community member invented a way to turn a standard school microscope into a web enabled one. This way, the microscope can broadcast its image via Skype or other video conferencing software. Using the free AutoDesk 123D Design CAD program, he designed an adapter that attaches a run-of-mill webcam to the microscope’s eyepiece. The adapter sets the webcam’s focal length perfectly for a clear picture. What an amazing way to repurpose “last generation” microscopes to web enabled equipment in a low-cost way!

Original microscope and webcam

Webcam adapter made with 3D printing

Some assembly required

The finished product!

Some of our students this semester are musically inclined. Josh is currently using the Solidworks CAD program to design a lap harp (also known as a chamber harp). He is printing the first piece of the instrument today; more news later as the project progresses. Another student found an excellent, pre-made ukulele design on Thingiverse. It is 3D printed in 10 parts, then assembled. He added some guitar string, tensioned it for the various pitches, and now has a working instrument. And it works rather well! He still has to learn how to play one, to the dismay of the strange music he was plucking. 🙂

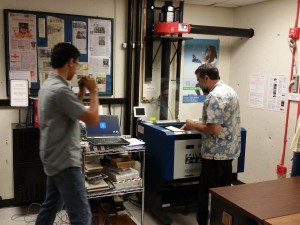

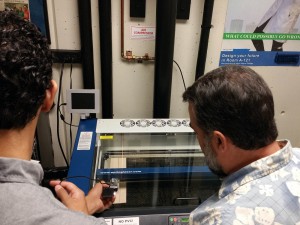

Earlier this week, we invited students from Dalton Middle School to the 3D Lab to learn laser cutting and engraving. They are building model helicopters using balsa wood. Students drew designs on-paper which were scanned and imported into Corel DRAW. The designs were used as backgrounds for tracing lines and boxes using the vector art software which are then be laser-cut onto the wood boards.

The neat thing is that it was a virtual field trip, using Skype to broadcast the activity from the 3D Lab to their classroom! Anthony did a wonderful job as cameraman. It was a big success and the students had lots of questions throughout.

Demonstrating Corel DRAW via webcam

Operating the laser engraver

Broadcasting laser cutting to the Dalton classroom

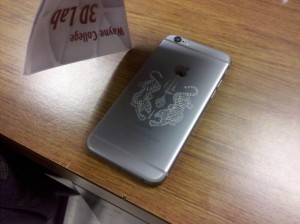

Speaking of laser engraving, a particularly brave student wanted to engrave a design onto the back of his iPhone. After some research, he discovered that the phone’s casing is made of anodized aluminum with is compatible with the laser engraver. The laser company (Epilog) publishes recommended laser power and speed settings for various materials, so we were all set. We placed a piece of acryllic on the phone for a “test engrave” to check the positioning of the image. Then the acryllic was removed and the phone engraved with the laser. The result was beautiful! Thankfully we did not cut the phone in half. 🙂

Stay tuned next week as we report on the 3D Lab’s involvement with the UA Baja Racing Team project!

3D printing technology makes contributions to third-world countries. See how this printer hopes to melts down and repurpose the world’s plastic, glass, metal, concrete, and other solid waste into new products.

See how his 40-foot 3D printer can build entire houses out of mud or clay”

http://www.gizmag.com/wasp-big-delta-3d-printer-clay-housing/39414

Until next week,

Tom