Hello everyone,

Sorry for the missing blog entry last week, as yours truly was on vacation and needed a break! Now back to the job and refreshed, it’s time to dig into the latest exciting things happening in the 3D Lab at The University of Akron Wayne College.

With engineering classes in full-swing, the 3D printed weighted cubes worked well for the LEGO Mindstorms robots that tossed them. Now students are building robots to carry and drag heavy loads. 3D printers are currently creating student designed sleds that their robots will pull. More about this activity in the next blog.

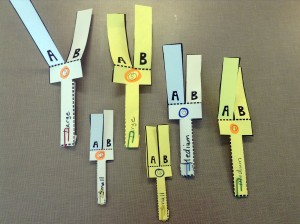

As mentioned last week, the 3D Lab offered a virtual demonstration of laser cutting and engraving to students of Dalton Middle School. The session was a wonderful success! Each student designed model helicopter parts with pencil & paper which were scanned into the computer, traced with vector art software, then laser cut and engraved. The results are shown below:

If you can’t visualize how these parts assemble into helicopters, then you are in good company; neither can I! But the instructor will reveal the final result when the helicopters are finished soon. The kids also made their own gravity helicopters out of cardboard and were visited by a real one landing in their schools yard a couple of weeks ago!

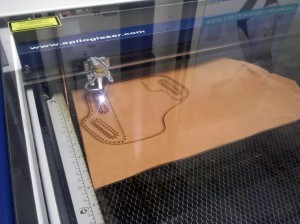

Earlier in the week, Nathan’s involvement with the Armed Forces prompted him to try a new project with the laser engraver, a leather gun holster made from scratch. Upon reading the engraver’s manual, we found that that the engraver fully supports engraving and cutting leather. This was especially helpful for cutting holes that are needed for stitching leather together. There were specific laser power and speed settings for leather, so with a little experiementing it worked perfectly! Suprisingly, the cutting process emitted a nasty odor that permeated the room.

The last step is wet forming the leather pieces into a mold around the firearm. We are interested to see how the final result will look. Good job, Nathan!

Last Friday, we took the portable 3D printer (provided by the Romich Foundation) to the Massillon Amateur Radio Club for a presentation on 3D printing and careers in engineering. Since 1927, the Club has been a diverse radio hobbyist club that is currently over 80 members strong. Active within their community as well as an ARRL Special Service Club, it is actively involved in many facets of Amateur Radio, including Public Service, Membership, Field Day, Repeaters, Amateur Television (ATV), Skywarn plus many other interests.

The room was packed with over 40 people. The presentation on 3D printing was so well received that members talked about it for days. As the group is technical in nature, they had many interesting questions, especially how 3D printing can benefit amateur radio and their personal lives.

Stay tuned as we cover more about the Mindstorms robotics project and other interesting things happening in the 3D Lab!

See how scientists are using 3D printing to deliver medicine using micro-needles:

http://phys.org/news/2015-09-scientists-d-printed-drug-micro-needles.html

A new production process makes PLA bioplastic cheaper and greener:

http://www.gizmag.com/bioplastic-pla-cheaper-production-process/38498

Until next week,

Tom