Hello everyone,

With the semester finishing its ninth week of classes, the 3D Lab is as busy as ever. Our two newest printers (Lulzbot Taz 5 printers provided by the Wayne County Community Foundation) have proven to be workhorses, running flawlessly practically all day, every day. Each day brings new activities with student assignments, community projects, club involvement, mentoring, and more.

We are also thankful for our older printers (two Makerbot and one Affinia brand printers provided by the Romich Foundation and Laura B. Frick Charitable Trust). Makerbot (based in Brooklyn, New York) is currently the most established consumer 3D printing company. They offer service plans that benefit our printers. Our first printer is currently at their repair shop and our other printer receives replaced extruder heads, as they fail, at no cost. Having extra printers available during failures keeps our labs available to students.

Earlier this semester, engineering students were busy designing flashlight bodies and related parts using Solidworks, a high-end CAD program. Now they are printing full-size versions of them. The designs look like this:

While the designs look excellent on-screen, they pose a challenge for 3D printing. Because printing is performed from the ground up, any overhangs need temporary posts under them for support. These supports drastically increase print time and filament consumption. You can see the overhang under the lip in the flashlight case, and how support material is printed to support it.

Students learn to change how something is designed so that it 3D prints as efficiently and quickly as possible. This redesigning not only saves time and money, but allows things to be created that wasn’t possible with traditional manufacturing methods. For example, see how this articulating robot can be 3D printed as one piece, without needing to be assembled.

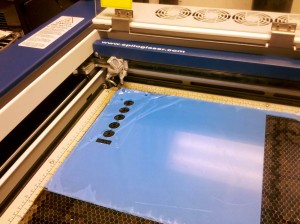

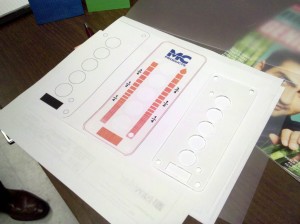

Over the past few weeks, a community member wanted to design replacement instrument panel covers for fire trucks. After talking through ideas with personnel and students in the 3D, we decided to laser cut the panels from clear acrylic. These panels would be overlays for changeable paper labels. They used free vector art software from LibreOffice which was imported into Corel DRAW in the 3D Lab. The laser cutter cut the designs beautifully while the paper overlays were color printed with an inkjet printer. The panel covers turned out beautifully!

We encourage visitors to learn the equipment and create things themselves; it encourages them to learn new skills. The community member and his associate did all of the work, with our assistance to run the equipment.

The 3D Lab went on a road trip earlier this week, this time to support the Wayne County CIRCLE Coalition and STEPS program. Serving Wooster, CIRCLE Coalition is the oldest substance abuse prevention coalition in Wayne County. It had its start from a group of concerned parents that worked together to prevent substance abuse. We took the 3D printer to a Harvest Bash event held at St. Mary’s Catholic Church in Wooster. Hundreds of children, parents, and young adults attended the event. Our 3D printer was a bit hit, as usual. Kids of all ages and adults alike were fascinated with the technology and excited to know about the availability of 3D Lab at Wayne College. We hope that new visitors will come to the lab to learn a new skill, hobby, or even future career! Thanks, Nonya, for inviting us!

We are thankful to P. Graham Dunn for their donation of materials for the laser engraver. Their generosity allows students and community members to learn laser engraving at no cost, makings gifts and useful things for themselves, friends, and family. This beautiful clock was engraved by a staff member who never used an engraver before. Now she is hooked! In the background are game boards for a marble game that were laser engraver and CNC routed.

Last but not least, we are thankful to Arden and Clarice Shisler for their recent donation to the 3D Lab! Consumables (notably plastic filament) is a continual expense. Their donation allows the 3D Lab to remain open for community use at little or no cost. Thank you!

See how 3D printing is being used to create soft body tissue:

http://hackaday.com/2015/10/28/printing-soft-body-tissue

See how 3D printed teeth can kill 99% of dental bacteria:

http://tech.slashdot.org/story/15/10/22/0142201/3d-printed-teeth-can-kill-99-of-dental-bacteria

Until next week,

Tom