Hello everyone,

With finals beginning next week, students are scrambling to finish projects, study for exams, and yet make time to have fun in the 3D Lab. Many times, all five printers are running simultaneously from student assignments and personal projects. Our original 3D printer (a Makerbot Replicator 2X provided by the Laura B. Frick Charitable Trust) needed repaired again as its left extruder could not be used. Our service plan with the company ensures a continual stream of replacement parts that we install; a very helpful service!

We are pleased to announce that the 3D Lab will have an electronics station that will incorporate a electronics learning kit (300 projects that can be built), an Arduino learning kit, soldering station, various electronic parts to learn from, and more. A knowledgeable community member visits the lab on the regular basis to help students with projects that involve electronics. We are thankful for his continued support (and our students appreciate his advice, too).

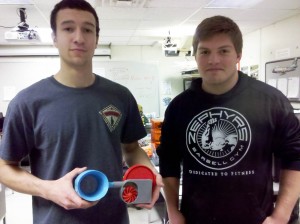

In our engineering classes, teams of students are tasked to build working fans by CAD design and 3D printing. Some students created Dyson lookalikes while others built traditional fans. All are working models to some extent. These complicated designs involves numerous interlocking parts.

Dyson-type fan prototype

Traditional “crank” fan

It pushes air!

Stay tuned next week for the “battle bots” competition. Students build robots from LEGO Mindstorms parts to each other outside a circle “arena”. Some of these robots will have 3D printed attachments to extend the capabilities of the stock LEGO parts. Results of the event are coming soon!

The Makerspace Open House at Schantz Organ Company in Orrville last Saturday was a huge success. Well over 70 people attended the two-hour event. The company hopes to open a makerspace where the public, businesses, and students can use high-end digital fabrication equipment at a reasonable cost. Attendees watched large-scale CNC routers in operation, experienced laser engraving, and learned about wood- and metalworking equipment. Wayne College demonstrated 3D printing, another popular topic for most. This enthusiasm reveals genuine community interest in makerspaces, giving them access to tools and technologies that we out of reach from previous generations.

President Victor Schantz explaining makerspace concept

3D printing demonstration

If you are interested in knowing more about the Schantz Makerspace initiative, please contact Victor Schantz at v.schantz@schantzorgan.com

Lastly, the Wayne College Flight Club is going strong, even nearing the end of semester when activities normally tune-down. We are pleased that a club president has been chosen for the Spring semester, so more high flying adventures and involvement by Wayne students and the Wayne County RC Club is assured.

The battered plane below is a glider that was enhanced by 3D printing. It can be towed by a powered plane hundreds of feet in the air, with a motor to release the tow cable on-demand. It is a testament to the inventiveness of our students!

Check-out the video here of the glider being towed and released. Don’t watch if you are afraid of heights. 🙂 Thanks, Chris and Nathan!

The laser engraver (donated by the Romich Foundation) continues to create amazingly diverse products. A staff member requested learning blocks for her grandchild. Barry Romich from the community provided the blocks that were sawed from a 4×4 post which were then sanded and painted. After the paint dried, the engraver removed paint to reveal the wood beneath. It truly was a group effort.

3D printing isn’t limited to making objects slowly, one-at-a-time. See how a mold was created to produce ear buds from silicon caulking:

http://hackaday.com/2015/03/13/3d-printed-molds-and-silicone-caulking

Selective laser sintering is a 3D printer that prints metal objects. A first in the industry, below is a desktop SLS printer that only costs $8,000!

http://hackaday.com/2015/09/10/sinterit-pulls-sls-3d-printer-entry-level-price-down-to-just-8k

Until next week,

Tom