Hello everyone,

With Finals Week nearing completion, the 3D Lab is beginning to wind-down for the winter break. It is still a popular place for student engineers finishing their LEGO robots, Flight Club meetings, and students crafting gifts for the season. We are very thankful to P. Graham Dunn for providing material for students to use. It gives them and community members practical skills while they make gifts for themselves and others. More about this below.

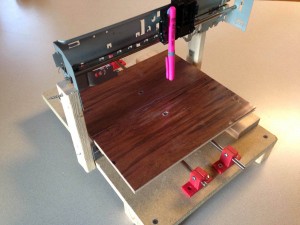

A particularly inventive student is fascinated with CNC routing. These machines route and carve wood using a Dremel-like tool that is computer controlled. Normally, small CNC machines cost $5,000 and up; Ben is determined to build his own for under $100!

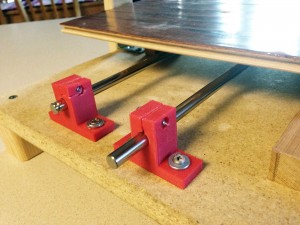

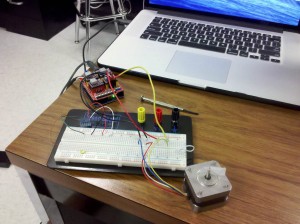

With the initial rough design, he uses a carriage and rods from an old inkjet printer, stepper motors from plotters and other machines, wood from his dad’s workshop, and 3D printed attachments. Controlling the router is an Arduino microcontroller with an attached “shield” to power and drive the motors. The motors will move the bed one direction (along the rods), the Dremel in the other direction, and the Dremel up & down, too. It’s a fascinating project and inspiring to see Ben so excited about it.

Rough draft of the CNC machine

3D printed rod braces

An Arduino controlling a stepper motor

A few months ago, a community member provided a car jack from a vintage British race car. He wanted to know if the 3D Lab could produce a plastic replica of the jack. The 3D scanner provided by the Orrville Boys & Girls Club was perfect for the job. The jack was scanned from various angles using a motorized platform that rotates the jack as it’s being scanned. All of the scans were then stitched together to form an onscreen three dimensional image. The image was cleaned up and polished in the scanning software, then loaded into the 3D printing software. After about 15 hours of printing, the duplicate jack is quite close to the original!

P. Graham Dunn generously donates material that allows students and community members to learn laser engraving (and other creative projects). There were a lot of crosses that needed good homes, so we thought that a retirement home would be a perfect fit. Dave from Shady Lawn Nursing Home in Dalton asked his fellow residents if they would like crosses for themselves, family members, and friends for the holidays. We spent two evenings engraving names, inspirational words, and pictures onto many crosses. The residents were thrilled! It is wonderful for the 3D Lab to give back to the community for so much that it has given to Wayne College.

Speaking of engraving, a student found a clever use of sawed wooden branch pieces; they make perfect coasters! She personalized each coaster with a laser engraved image. The largest piece was used for a “words of thanks” plaque that her father wrote when he was young. It’s all beautiful.

In the medical world, see how 3D printers have successfully 3D-printed anatomically correct models of patients’ vascular systems for pre-op practice:

3D printing soft body parts: a hard problem that just got easier:

Until next week,

Tom