Hello everyone,

It has been a hectic couple of weeks in the 3D Lab. Or, since last week, an empty room! Our Maintenance Department graciously offered to clean and wax the lab’s floor which was quite filthy from two years of high traffic. That meant removing everything from the lab. For many of you who visited the 3D Lab, you know how tightly packed everything is with machines, furniture, equipment, etc.

It only took two days to remove everthing, but over a week to install stuff back into place! The lab should be mostly functional by the start of fall semester. We literally had folks coming in the door to use machines after barely setting them up, so it’s been a fast paced week. 🙂

And thanks to the fast work of the Maintenance Department, we were ready for the influx of new students on “Wayne Day” yesterday! Wayne Day is a wonderful way for new students to get acclimated to Wayne College, a flurry of activities and information to prepare them for starting classees next week.

Julie Gingery, Office Support Specialist at Wayne College, invented a cool project for Wayne Day that involved laser-cut stencils that students air-brushed onto t-shirts. She created dozens of word based stencils in Corel DRAW (such as “Engineering”, “Chemistry”, etc.), edited the words as vector art to have connected letters, then lasered the designs into 3/8” MDF board.

On Wayne Day, students chose their own phrases which placed on t-shirts and then air brushed. The stencil is then removed and the t-shirt ironed to dry/fuse the paint, leaving the stencil’s outline with a “glow” around it. Students were lined up for custom-made t-shirts!

Dozen of students also visited the 3D Lab on Wayne Day. We showed them how to make custom designed water bottles, courtesy of P. Graham Dunn. We engraved almost 40 unique bottles, another big hit with a line of students waiting to the door! Many thanks for P. Graham Dunn for making this activity possible.

Earlier this year, one of our Akron campus students used our Electronics Station to work on his latest invention, a velocity-dependent slow moving vehicle bicycle taillight system for his senior design project through the UA Human Powered Vehicle Team. The system will automatically light-up the brake lights as “parking lights” while the bicycle is in-motion, change their intensity based on bike speed, and flash them when cars are approaching from behind.

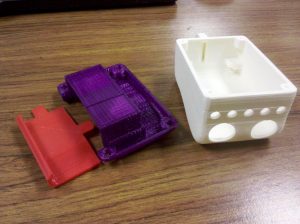

Powered by a low-cost Arduino Uno microcontroller, accelerometers, proximity sensors, LEDs, and other hardware, Don also designed and 3D printed a custom enclosure for it (above). Since then, Don refined the hardware enclosure, making it much more portable and fittable for bicycle mounting. The finished design is below:

It’s wonderful to see how 3D printing is used for rapid prototyping, getting ideas out of our heads and into our hands in literally a few hours.

Earlier this summer, the 3D Lab made another road trip, this time to the Wooster Boys and Girls Club held at Wooster High School. Our second visit to this group, kids were still brimming with questions and amazement at the portable 3D printer that was brought to the presentation.

We talked about applications in 3D printing, careers in engineering, the 3D Lab at Wayne College, and announced the upcoming Wayne County Mini Maker Faire in May 2017. In particular, we talked about how 3D printing can solve problems in photosynthesis, sound, and space. The latter was most interesting as we talked about how photos of Comet 67P/C-G taken by the Rosetta spacecraft were converted to a 3D object for printing a miniature of the comet itself.

Stay tuned next week as we begin a new semester at Wayne College with bright, new minds building all sorts of interesting projects in the 3D Lab!

See how at-home 3D printers may be the future of home cooking:

http://www.eater.com/2016/8/2/12353172/3d-printer-cooking-columbia-university

See how this 3D food printer is designed to cook-up culinary creations:

http://newatlas.com/columbia-engineers-food-3d-printer/44689

Interested in making your own custom t-shirts? Build this personal silk screening machine for $20!

http://www.instructables.com/id/20-Portable-Silkscreen-Kit

Until next week,

Tom