Hello everyone,

Between a long holiday break and catching up with a mountain of work afterward, I resume posting the activities in the 3D Lab. And busy it has been! There are so many things to say, so many stories & projects, and the excitement of new possibilities on the horizon that this blog barely scratches the surface.

One such announcement is the introduction of the new Maker Lounge! Located just outside the 3D Lab, the lounge allows students to relax, socialize, collaborate on homework, and, most importantly get ideas started with 3D printing and anything else we have to offer in the 3D Lab. The lounge has couches, study tables, a whiteboard, two 3D printers (courtesy of the Romich Foundation), a coffee/pop/snack station, dye sublimation printer (courtesy of the Aldrich Family) and a collaborative design table. The lounge serves as way for more students to get interested in being inventive and creative. We still have a ton of work to do, but the lounge should be ready by next week! Many thanks to Dean Jarrod Tudor for making this possible.

Even though Fall classes ended in mid-December, the 3D Lab has been a beehive of students and community members working on projects. Our student staff Josh and Nathan were inundated with folks on one particular day, particularly those making homemade Christmas presents. Nathan regales the experience:

“Wednesday, the 21st, was a really crazy day. It started out pretty simple, it was just Josh and I working, and two of our friends who had come in to work on projects. Around 12, two gentlemen came in to continue some Christmas projects they had come in and started Monday. I was helping them, while Josh started working on another project for the room. Then, right around 12:45, it was like someone made a public announcement to come to the lab, because within the span of about 20 minutes, we had an additional 10 people show up to work on projects in the lab, most of them for Christmas presents. With only Josh and I there, we couldn’t even keep up for all the projects that were there, and we actually had to tell some people to come back the next day, because things like the laser engraver and dye-sub printer were so busy, they wouldn’t even be able to start their project before the lab closed. So after those couple people left, we were able to devote the rest of our time to helping people get their presents done before the lab closed, which kept us busy to 3 and beyond, we were off the clock, but we still stayed for the next hour and a half helping people finish their projects before the lab was closed, and doing as much on others as we could so that the next day they would’ve close to done. All in all, one of the busiest days in the lab I’ve ever been a part of in my year working there.”

Earlier last month, Nathan, Kristin Foy Samson, and I traveled to Fairless Middle School in Navarre on an early, cold, and snowy morning. It was the school’s annual “Career Day” event where community members from many walks of life inspire students with job possibilities. We spoke to six classes about going to college, considering a career, what engineering is like, and demonstrated 3D printing. It was an exhausting day, but rewarding because of the excitement and barrage of questions from the many students. We made a lasting impression on these kids, that’s for sure!

Another big announcement is a generous grant from the John Kaylor Memorial Fund, a component fund of the Wayne County Community Foundation. It will be used to purchase a 3D milling device and consumable supplies needed for continued public use of the Wayne College 3D Lab. A milling device allows carving and cutting soft woods and plastics with four or five degrees of freedom. It can create objects that are sometimes not possible with 3D printing. We are really excited with the creative possibilities that this milling machine will bring to our students and community members. Our student engineers have certainly been asking for one!

Speaking of woodworking, mark your calendar for the next Maker Monday on Monday, January 16th at 7:00 p.m. at The Schantz Organ Company in Orrville. They have a lot to announce during this meeting, especially about progress on the community-made CNC machine class.

Part of the agenda for the upcoming Maker Monday will be to showcase the prototype machine and have CNC Machine Build Class students on-hand to talk about their experiences so far. They have been making various projects on the prototype machine, learning the software, working with hold-down devices and dust collection equipment, and generating new ideas on how to test the machine.

Remember, too, that Maker Mondays are a place to share what you are working on. Sometimes it helps to bring your project and let others comment or answer your questions. The people in our maker community bring many different kinds of experience to the table. We are all about collaboration. If you want to know more about Maker Mondays, please contact Vic Schantz at v.schantz@schantzorgan.com

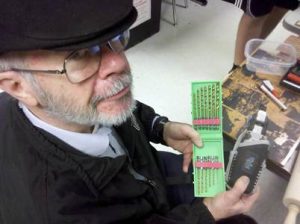

Last but not least, community member Vern recently used our Taz 5 3D printer to create a folding drill bit case for his quick-change drill. The bits themselves are secured using braces made with NinjaFlex rubber filament, while the case itself was printed using HIPS filament. Vern invented the hinge on the case, though the printer extruded too much plastic, causing the hinge to partially fuse together. But with a carving knife and a little elbow grease, the case opens and closes perfectly now!

Speaking of printing with plastic and rubber, how about a multi-material 3D printer squirts out homemade electronic circuits:

http://newatlas.com/nexd1-multimaterial-electronic-3d-printing/46941

See how this tough, 3D-printed drone features embedded electronics:

http://newatlas.com/drone-3d-printed-embedded-electronics/46710

Turn your Dremel rotary tool into a mini drill press using only $20 worth of materials!

http://www.instructables.com/id/Drill-press-for-20-21

Until next week,

Tom