Research

F.1 Topic 1: Materials discovery for advance additive manufacturing of polymer composites

F.1.1 Motivation and significance: Current composite fabrication technologies do not produce systematic data to yield input-output relationships in ML algorithms for prediction of materials properties. One cannot easily infer from existing literature the resin systems that are amenable to additive manufacturing or known to produce certain desired properties in the final FRP composites. Extrusion printing uses concentrated viscoelastic inks which exhibit thixotropy in the absence of flow stress, but undergo shear thinning to allow extrusion through micro-nozzles under ambient conditions without requiring prohibitively high printing pressures. The printed domains retain filamentary shapes due to thixotropy. Therefore, the ink composition and rheology must be tailored to control the printability, architecture, and the properties of patterned AM structures. Resins that are used in the aerospace applications include thermally-cured epoxy, bismaleimide, and cyanate esters. Often fillers are added to improve the toughness of cured resins. Epoxy-based FRP composites dominate the high-volume aerospace and automotive market due to their high thermal stability and robust mechanical properties. Cured epoxy resins show Tg typically 120–180 ºC and tensile strengths 35–41 MPa]. The proposed research will consider the epoxy resin systems primarily due to its large volume market capitalization in aerospace industries and its tunability to suit AM requirements, such as optional blending with a photopolymerizable resin and printability by material jetting.

F.1.2 Module 1. Discovery of new and novel resin systems: The trainees will learn synthesis of epoxy/curing agent or epoxy/curing agent/acrylates resin systems. Currently, only limited data exist on direct ink writing (DIW) of epoxy resins while dual-cure (epoxy/acrylate) resin system appear more attractive. The concept of combinatorial chemistry will be used to generate data, i.e., systematically altering the preparation parameters and obtaining the properties of the resulting cured resins through Molecular Dynamic (MD) simulation and experimental measurements. Bisphenol A diglycidyl ether, bisphenol F diglycidyl ether, and neopentyl glycol diglycidyl ether will be considered as starting points and curing agents, curing conditions, and curing time will be screened.

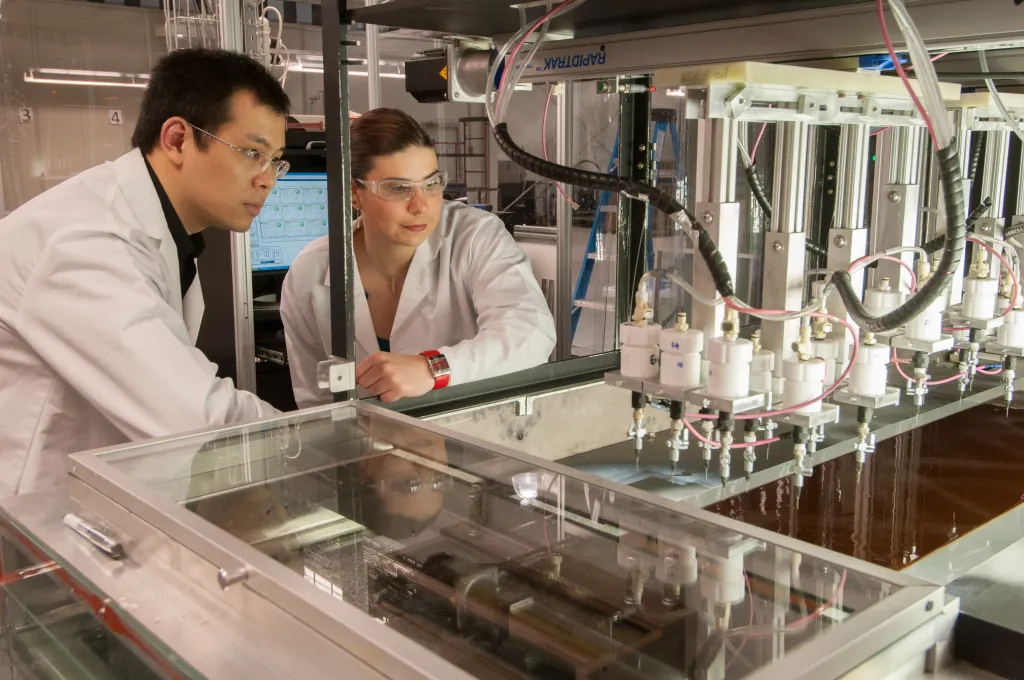

F.1.3 Module 2. Additive manufacturing process: Trainees will configure thermoset resin systems data from published work and from proposed research into searchable databases against Tg, decomposition temperature (Td), elastic modulus, gel time (tgel), cure time (tcure), toughness, liquid surface tension and spreading coefficient, solid surface energy, liquid viscosity, and solid viscoelastic properties.Fundamental knowledge will be generated as enabler of additive manufacturing of FRP composites from thermoset resin systems. New research on printability of thermoset resins on mats of continuous fibers via DIW will generate composites properties data as function of printing speed, feature dimension, gelation/curing time, shear rheology, orientation of dispersed fillers/rheological modifiers, shape relaxation of features, fiber wetting, and shelf-life of printed mats.The trainees will evaluate sheet molding technique as a means for complex shaping of DIW FRP composite sheets.

F.1.4 Module 3. Structural functional performance: Trainees will use ML driven approach to understand how manufacturing parameters and resin chemistry affect structural performance of composites and utilize suitable ML algorithms to build predictive analytics models that could accurately predict the mechanics and performance of composites with a small number of input data. Further investigation using experiments and modelling will lead to the structural and functional performance of composites at high-temperature to demonstrate high-temperature stability, tailorable stiffness, and unique ductility in conjunction with characterization of a set of room/high temperature mechanical properties.

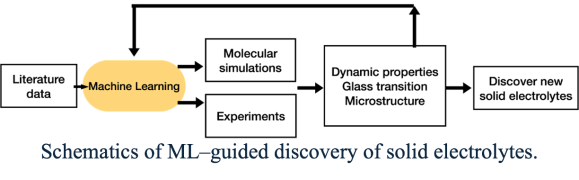

F.2 Topic 2: Identifying solid state polyelectrolytes with superior conductivity for broad range of applications such as aeronautic, automotive industries, solar power storage

F.2.1 Motivation and significance: The performance of lithium-ion batteries (LIBs) is determined by the ionic transport in the electrolyte. Two key parameters that determine the ionic transport are the conductivity and viscosity (or strength) of the medium. It has been suggested that polymer-based polyelectrolytes provide a high modulus with appropriate conductivity. Although LIBs provide reasonable power sources for many applications, the safety concerns arising from the flammability issues hinder applications in aeronautic missions. In this context, the maximum operating temperature of polyelectrolytes synthesized using amorphous polymers is low while the use of solid-state polyelectrolytes based on high melting crystalline polymers and additives such as magnesium oxide (MgO) expand the upper limit of usage temperature. In view of the above, the NRT trainees will study identification of the mechanism of ion transport in polyelectrolytes systems using the two approaches presented below.

F.2.2 Module 1. Dynamics of ions in crystalline polymer domains: Ions show slow dynamics due to ion aggregation and due to coupling between the polymer and ion dynamics via intermolecular interactions. In this project, the trainees will use atomistically-detailed molecular dynamics (MD) simulations to study the dynamics of ions in the crystalline domains of the polymer. The mobility of ions and the conductivity of the polyelectrolytes will be linked to the chemistry of the monomers and the melting temperature of the polymer. The MD simulations will yield the interactions between ions and polymer and the underlying transport phenomena of the ions in electrolytes composed of solid polymeric materials.

F.2.3 Module 2. Machine learning algorithm for rapid screening of polymers: The trainees will use ML algorithms to identify the solid-state polyelectrolytes that give high melting temperature and high conductivity, given that there is an extended parameter phase space to optimize the effectiveness of the polyelectrolytes and that performing atomistically-detailed MD simulations for all the candidate materials is computationally expensive. Thus, the research plan involves the use of a combination of MD simulations, experiments, and ML methods. A thorough literature review will identify promising polyelectrolytes with favorable parameters studied in prior work. MD simulations and experiments in combination will allow prediction of Tg of solid electrolytes and diffusion coefficient of ions. These will be fed back to update the perception of the ML models. The ML model learns from each MD step and provides informed guidance for the navigation of the extended parameter phase space. The ML algorithm will be based on Bayesian optimization, recently used to study the polyelectrolytes from polymer blends. The results will yield new information on solid polyelectrolytes such as optimum molecular weight, chemical structure, and the degree of polymerization.

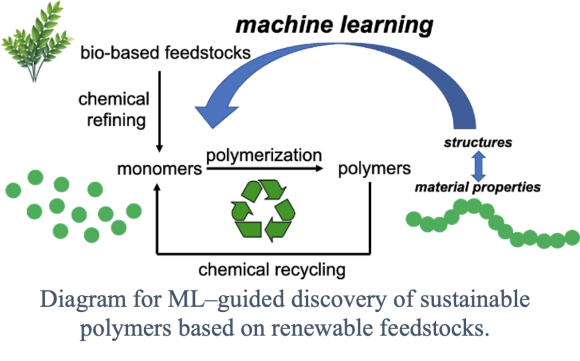

F.3 Topic 3: ML–guided discovery of sustainable polymers based on renewable feedstocks

F.3.1 Motivation and significance: Synthetic polymers such as plastics and rubber are used in nearly every aspect of modern life driven by their durability and versatile thermomechanical properties. However, the same excellent thermal and chemical stability of commercial polymers serve as deterrent to recycle and reuse. Currently, most polymer products are consigned to landfills or thrown into the ocean, causing serious environmental concerns. This consumer behavior pushes the next generation researchers to strategize the usage of finite fossil resources such as petroleum and coals for production of polymers and to find measures that counter the consumer inability to recycle. Efforts to address these issues include the development of biodegradable polymers and mechanical recycling. However, most biodegradable polymers that can be degraded in artificial environments do not undergo efficient degradation in seawater, giving rise to new environmental consequences. Mechanical recycling of polymers typically results in substantial loss of quality, and the recycled material is not suitable for high-performance applications. Polymers that can be chemically recycled into the constituent monomers for repolymerization are promising candidates to address the challenges in plastics sustainability as they provide a mechanism for the circular use of the materials. The prospect of commercial success of new sustainable polymers depends on their properties matching or exceeding those of current commercial polymers. Polymers that can be broken down into small molecules (i.e., degradable polymers) have received considerable attention as an option for sustainable materials. Trainees will conduct research in this area using two modules.

F.3.2 Module 1. Synthesis and chemical recycling of the bio-based depolymerizable polymers: In this module, the trainees will develop chemically recyclable polymers from bio-based feedstocks to reduce the reliance on finite natural resources (Figure 5). The work of Mecking and coworkers demonstrated that inserting small numbers of ester or carbonate groups on polyolefins enable recycling of the polymer without significantly compromising the material properties. This serves as an inspiration for the proposed work whereby polymer backbones with small number of degradable bonds will be synthesized by polymerization of diols and dicarboxylic acids with long alkyl chains. The abundant options of bio-based feedstocks with diverse structures of monomers and polymers will allow tuning of the material properties to a desired target. The trainees will also study depolymerization methods to recover the monomers from the newly synthesized polymers. The depolymerization kinetics will be investigated under different pH, different temperatures, different solvents to establish the degradation profile critical for recycling of the materials.

F.3.3 Module 2. Structure–property relationships of chemically recyclable polymers: The crystallinity is an important property to render robustness in sustainable, chemically recyclable polymers. Crystallinity enhances the chemical resistance of polymers and allows them to be used above Tg. The Tgs and crystallinity of the polymers will be systematically tuned and the molecular structure-thermal property relationships will be established. Specifically, the influence of (1) stereochemistry of the substituents, (2) length and size of the sidechain, and (3) branched sidechain on Tg will be evaluated. Once polymers of a broad range of Tgs and crystallinity are identified, the trainees will synthesize elastomers and plastics and determine their mechanical properties. These sets of experimental data will be analyzed using ML tools to identify the ideal structures of polymers and monomers, which in turn will guide the selection of bio-based stocks. A new class of chemically recyclable polymers with tunable thermal and mechanical properties will result from this work. The data collected from this project and the approach of ML-guided material discovery will be useful for designing next-generation sustainable polymers.

F.4 Topic 4: Tuning data management and ML tools to advance materials science research

F.4.1 Motivation and significance: Recently, ML was used in material discovery by capitalizing on large-scale data for the prediction of the material properties and for acceleration of the discovery of new materials. Existing methods to store and manage composite data generated from experimental and simulation work face challenges from various data formats, data from multiple sources, and large data volumes. Several polymer databases such as PolyInfo, Polymer Genome, Polymer Property Predictor and Database, and CROW have been developed. These existing polymer properties databases contain property data points of various kinds of polymers, but the data are primarily on properties of linear polymers and the influence of crystallinity or glassy domains cannot be easily inferred. Thus, they are not sufficient in guiding additive manufacturing of fiber-reinforced polymer composites of thermoset resins, material selections for solid polyelectrolytes in LIBs, or monomer systems for degradable polymers. There is a growing need for developing a scalable materials database that is findable, accessible, interoperable, reusable, and useful to the polymer research community ML was coined in 1959, but it has become prevalent today because of increased data volumes, advanced algorithms, and advances in computing power and storage. To date, ML has already had great impact in fields such as voice recognition, computer vison, computer gaming, and fraud detection. ML has also been playing increasingly important roles in advancing materials science.

F.4.2 Module 1. Developing a scalable composite data management system: This project will create a scalable composite materials database that is integrable with existing polymer repositories and can be used to develop novel composites. The database provides accurate, secure, and consistent data to composite research community and is shareable with composite researchers for input training and refinement of ML models. The web-based interface of the database will embed a large scheme of linear and nonlinear predictive models and ensemble modeling techniques for improvement of accuracy of predictive analytics. The proposed scalable composite materials database fulfills the following requirements: 1) Easily accessible composite database which allows user-upload data to integrate with existing reference data; 2) Database with flexible schema capable of handling the specifics of all types of materials and process data, including multi-dimensional property data, and various data types specific to composites; 3) Scalable data management system has the ability to manage high volumes of data in order to capture the full process and testing history of every composite used by a research project.

F.4.3. Module 2. Machine learning tools for materials research: Traditional approaches in the search of new materials are often conducted through iterative trial-and-error procedure. Molecular dynamics (MD) in materials on all scales advanced the search and allowed researchers to explore the phase and composition space far more efficiently. However, MD, especially the ab initio MD calculations, is computationally costly. The proposed NRT training in ML algorithms will focus not only on the basic principles, workflow, and pros and cons of the current ML algorithms, but also on exploration of new ML techniques to obtain novel materials of desired properties. Specifically, this project will develop an intelligent agent, a ML model, that provides feedback loop to MD simulations in navigating the composition space, learning and predicting the properties of compounds generated from combinatorial synthesis. Although ML has remarkable capabilities, one major drawback is that some models make the interpretation a challenge. In developing the proposed AiMS ML model, the 1st step of ML workflow will focus on novel feature selection techniques. The molecular compounds are 3D due to arrangements of atomic elements. Molecular descriptors have been described and studied in early work. This project will study a mixed set of features at different abstraction levels that include features descripting conditions of polymerization process, graphs representing monomers and the bonds formed during materials fabrication, and simplex representation of tertiary structures. Graph is a natural fit for describing molecular compounds in 1D and 2D and graph theory provides a systematic approach to identify the key elements in a compound including chains, branches and rings. The proposed descriptors are representative and comprehensive, and a variety of ML models can be applied, which will assist the interpretation of model and speed up the search of desired novel monomers. During the process of navigating the composition space, a large size of the descriptors will be expected. This project will explore various dimension reduction techniques including canonical-correlation analysis and principal component analysis to improve efficiency.