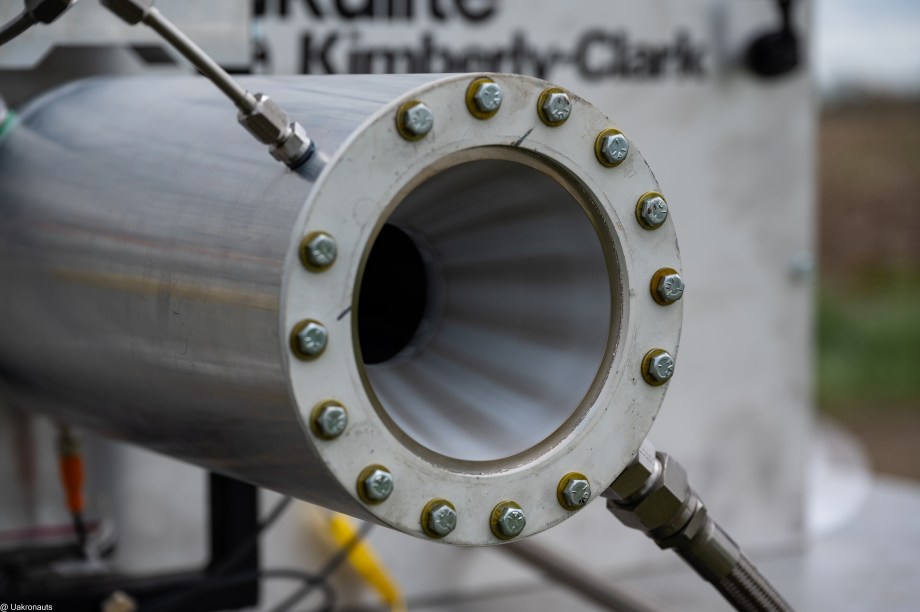

STINGER ENGINE:

Thrust:

sdf

2000 lbf

Chamber Pressure:

315 psi

Fuel:

Ethanol

Oxidizer:

Liquid Oxygen

Mixture Ratio:

1.2

Injector Type:

sdfs

FOF Triplet

Burn Time:

35 sec

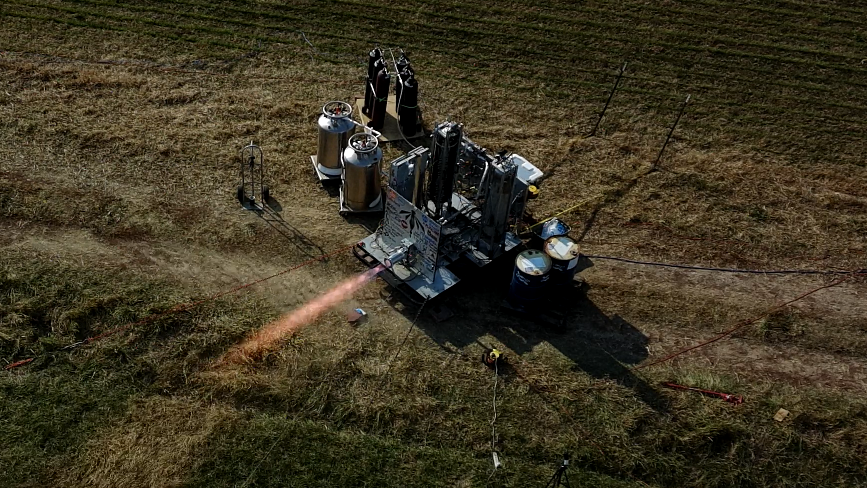

STINGER BLOCK 1

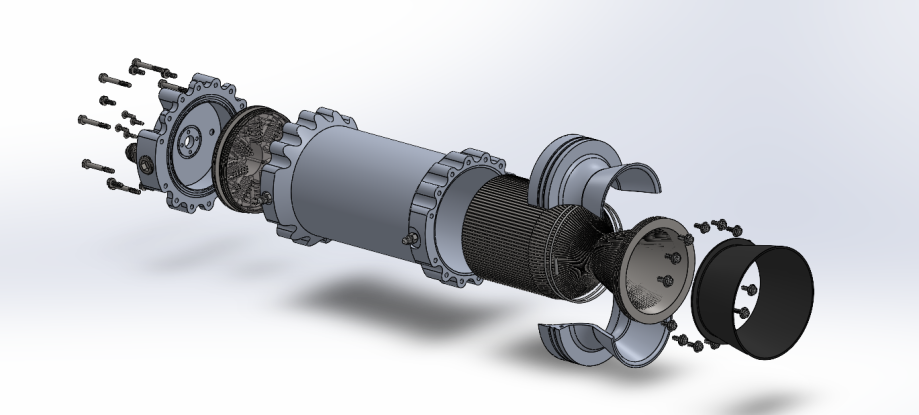

The Akronauts’ most ambitious project yet, a cryogenic regeneratively cooled engine dubbed “Stinger”

Traditional manufacturing methods. Machined in-house at the University of Akron College of Engineering machine shop.

Utilized regenerative cooled channels & film cooling despite the manufacturing complexity

Designed and tested two injector types, an FOF triplet and a LOX-centered pintle

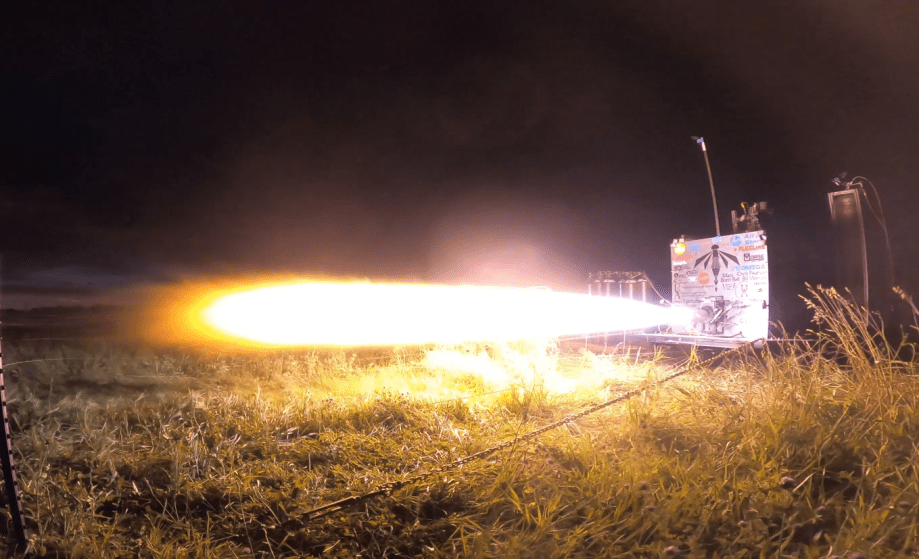

Hotfired 5 times from April to August of 2024

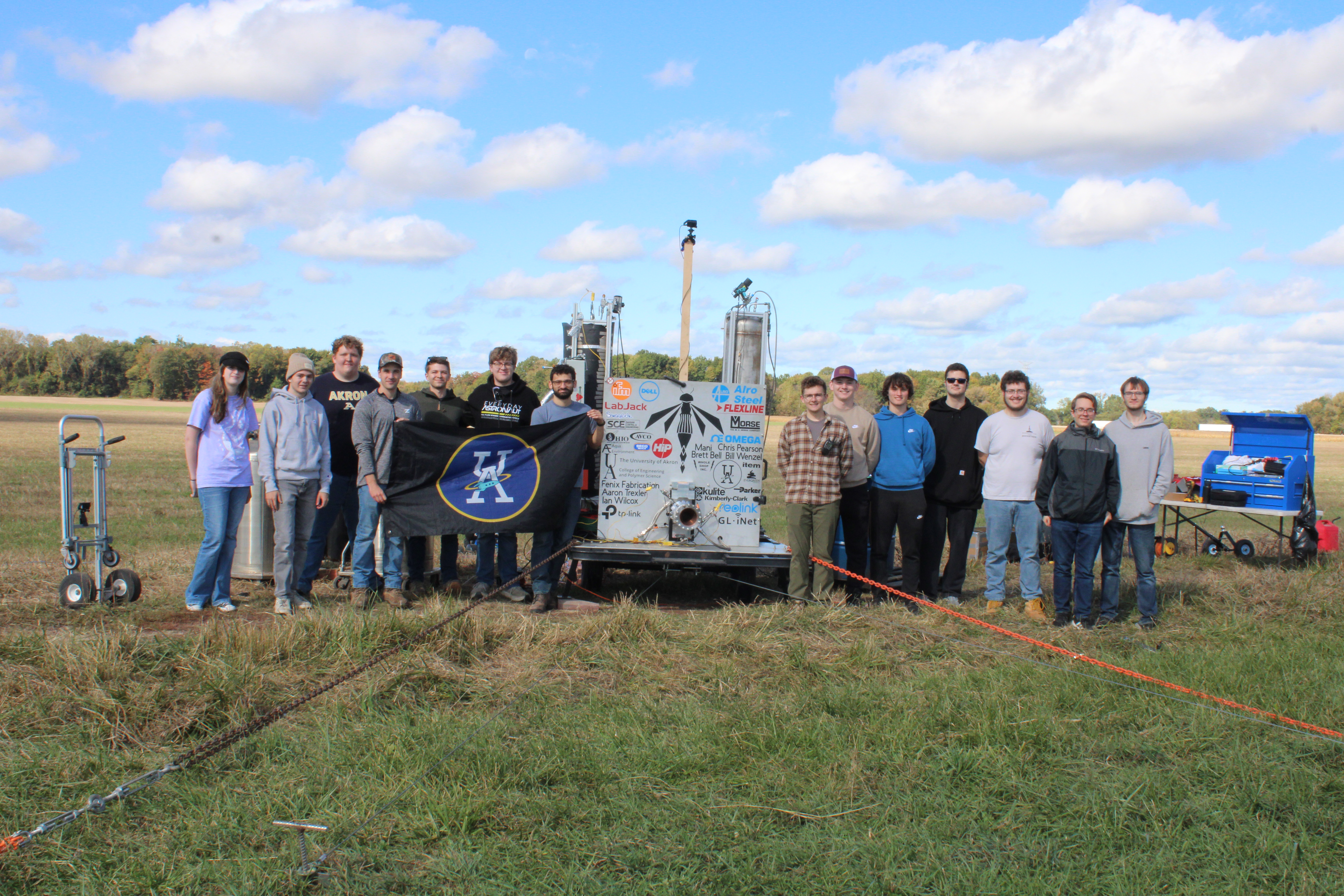

The Akronauts Rocket Design Team has once again pushed the boundaries of collegiate rocketry

The University of Akron News

STINGER BLOCK 2

Improvements: Optimized chamber design for flight vehicle perfomance. Weight reduction to overall engine assembly.

Results: Engine hardstarts led to multiple iterations of injector designs. 6 hotfire attempts from February to July of 2025 with 3 successful ignitions.

STINGER BLOCK 3

Improvements: Traditionally machined copper injector and chamber. The chamber was replaced with the Block 2 stainless steel version for the latest iteration of the engine.

Results: Hotfired 2 times within 1 week in October 2025. After a successful 35 second burn, the Akronauts are ready to put Stinger into a flight vehicle!