With summer classes starting this week, the 3D Lab is taking a break to recover from a hectic Spring semester. We have a lot of work planned to improve the room and prepare for the coming semester. Some of the larger projects involve the installation of the laser engraver and resin 3D printer, improvements of our filament recycling system, and preparing for summer camp with the Orrville Area Boys and Girls Club. We are thankful to have staff in the 3D Lab over the summer to help with these endeavors.

Early last month, the Replay for Kids organization hosted a workshop at Wayne College. Volunteers modify toys and assisted devices with switches that enable children to play with items like those without disabilities. The event was a big hit with plenty of volunteers modifying toys with easier methods to activate their features through larger buttons, switches, etc.

The 3D Lab was involved with this event, too. Earlier in the year, Kenny started work on modifying a large push light to act as a toy activation switch. Nathan (a 3D Lab staff member and mechanical engineer), continued his workby creating a baseplate and ring to support the modified light switch. The result is a button that is easy to press from any angle or amount of force. Replay for Kids requested over 30 rings to be printed, so we will be quite busy this summer!

For much of last semester, a Wayne student exceptionally talented in CAD design designed a mounting frame from for a custom, water cooled computer that he is building. His design is a complex collection of connecting parts and plates, all designed with AutoCAD Inventor. The frame was printed with our Makerbot Replicator 5th Generation printer for most parts (PLA plastic), while the remaining parts were printed in ABS for the high-heat areas of the motherboard. The result is amazing, a true testament to what can be accomplished with a little ingenuity and 3D printing. We are excited to see the finished product!

The model R/C Airplane Club has been a popular venue for students last semester. Resources in the 3D Lab aided in creating many plane designs, some plans downloaded from the Internet and others totally invented by students. Nathan found an online design for a single-wing airplane with no body, nosecone, nor tail. The plane propels itself from a rear propeller with two battery packs embedded in the wing.

Not content with the basic plane design, he enhanced it with a high-power controller which allows the plane to be controlled up to two miles away! It is also sports a camera which can be viewed on a wireless monitor. The plane is a marvel that seems to defy the laws of physics when it is in flying.

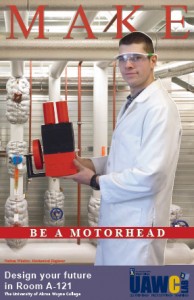

Last but not least, a cooperation between the Wayne College Library, Word Processing, Marketing Department, and our own students produced a series of posters to promote the 3D Lab in particular and makerspaces in general. These are high-resolution posters highlighting the best creations from the 3D Lab over the past year. Feel free to download and hang these posters in your schools and organizations! They are really well-done. Thanks to all who have helped these promotions materials become a reality.

Please click here for a list of all MAKE posters available

When [aimzzz] met a puppy born without arms, the need for some assistive hardware was obvious. We love it that rapid prototyping techniques have become so accessible that something like building a wheelchair for a puppy is not just affordable, but a lot of fun, too!

http://hackaday.com/2015/05/04/printing-puppy-prosthetics

See how an injured turtle was returned to the ocean with 3D printed beak:

http://www.gizmag.com/injured-turtle-3d-printed-beak-pau/37549

Until next week,

Tom