Hello everyone,

We are into our third week of the 3D Lab summer camp where kids from the Orrville Area Boys and Girls Club build radio controlled airplanes using laser cutters, 3D printers, and other technology. Anthony is learning the ins and outs of the new resin 3D printer, while Kaleb is laser engraving items for the first time. It’s amazing to see how busy the 3D Lab is, even in the middle of summer.

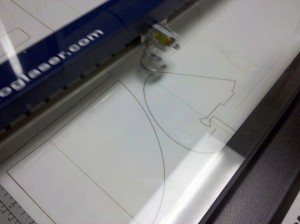

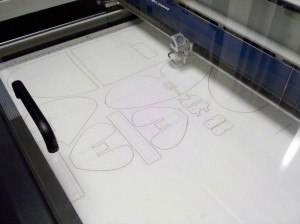

Last week, Chris (our camp instructor) showed the kids how to laser cut their planes from a single sheet of foam board. He created an amazing setup where the laser cutter uses different intensities of laser beams during a single job. One beam cuts through the board, another beam cuts half-way for folding parts, while a third simply scores the paper coating for marks. The couple dozen plane parts were easily created as a single print job. The kids were amazed!

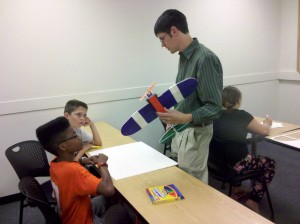

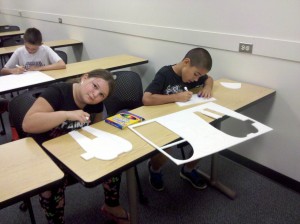

After cutting the plane parts, the kids were taken to a nearby classroom to color their planes with washable markers. The customization gives them a sense of ownership and pride in their designs, many of which are quite colorful. The kids had a blast and are eager for the next camp session when they will assemble their planes.

Last weekend, the Cleveland Public Library hosted its annual Mini Maker Faire. Over a hundred exhibitors displayed inventions and creative works to interest all age groups, from robots to egg-drop activities to trapeze swinging. As usual, lots of 3D printers were on display. There were plenty of activities for adults and kids alike, such as learning how to solder LED lights and biosensors. Over 4,000 people attended! In case you are interested, Akron hosts the next Mini Maker Faire on September 19, 2015. Don’t miss it!

Trapeze artist

Mobile robot that launches Nerf balls

Learning to solder a bio sensor

Huge bubbles

Making art from a dumbbell and a pendulum

Machine that picks, places, and solders surface mount devices (SMD)

Now into our second week of using the new resin 3D printer, we are still amazed at the quality and detail of its objects. Earlier in the semester, an Akron campus student used our 3D Lab for a project that requires custom bolts with threads. Our existing 3D printer made barely functional parts, as seen here:

The student is still working on this project, so we offered to reproduce the parts with our resin printer. Even with the printer’s “draft” mode at its lowest resolution, the results are still amazing:

One thing we discovered is that, depending on how the object is oriented in the software, some resin stays wet; it does not get fully cured by the laser beam. Also, properly oriented parts are initially rubbery and slightly sticky. We are currently planning to build a ultra-violet “light box” that will fast-cure resin, resulting in solid-hard objects in less time. Stay tuned as we work more on this project.

We added a new section to the 3D Lab website that highlights our “big projects” completed each semester.

Click the graphic to browse through our project highlights, all downloadable as PDF to use as posters to inspire your own students!

Did you know that 3D printers can make objects out of metal? The process is called “laser sintering”. See how sintering makes these impossible faucet designs that still flow water:

http://www.boredpanda.com/3d-printing-faucet-design-american-standard-laser-sintering

See how a 3D printed platinum-alloy thruster reduces waste, production/material costs and offers a adding a greater level of flexibility in terms of supply and demand construction.

http://www.gizmag.com/esa-3d-printed-platinum-thruster/38112

Until next week,

Tom