Hello everyone,

It seems there is so much activity in the 3D Lab that I can’t keep up with the news. And that’s a good problem to have. Students, staff, and community members are using it for many different reasons. It is rewarding to see people coming to the lab with different goals and projects, yet coming together to help with each other’s projects. We have community members giving advice to students, students helping employees, and lab staff helping everyone. It’s a wonderful way of exchanging ideas and forming a learning community.

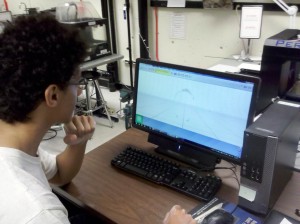

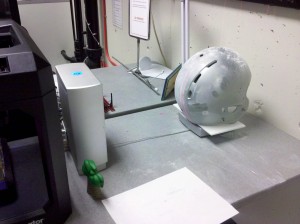

A few weeks ago, a local business found our website and requested use of the 3D scanner. Their intention was to scan a full-size football helmet, forming an outline to design peripherals that would fit comfortably inside. Our own Anthony accepted the challenge.

The helmet was made of a shiny plastic. The 3D scanner uses laser to gage the shape of the helmet, though the shiny plastic surface reflected the beam too much. Anthony applied a talc-like powder to dull the surface to provide a good scan into the computer.

Although the helmet’s image is now in the computer, the scanner software is primarily mean to reproduce another helmet. The person requesting the help wanted the helmet into a CAD program, which is an optional software upgrade that we do not have. Still, the image was enough to get them started with their project. Many thanks to the Orrville Boys and Girls Club for loaning the scanner; we are using it for a number of unusual requests!

Maureen from our library asked the best way to create a sign to be used for new movie theater. She already has a black, corrugated plastic board. We decided that the vinyl cutter would be perfect for the job. Her husband designed the graphics with a vector art program. The vinyl cutter did wonderfully with a big job like this with many intricate cuts!

After the vinyl was cut, the next trick is transferring the design to the black plastic board. We first cover the vinyl sheet with “transfer tape”. When peeling off the transfer tape, the vinyl sticks to it instead. Then the tape is pressed into the black board, and the vinyl goes to that. Given such a large sign, Maureen had a staff and community members help her with the transfer!

The Orrville Area Boys and Girls Club summer camp is into its fifth week. For this session, kids mounted propeller motors into 3D printed motor mounts and attached guide wires that move the rudders and ailerons with servo motors. The kids couldn’t be more excited as they completed the final steps to making their planes air-worthy.

Chris teaching assembly steps to class

Nathan building a “wing plane”

Mounting the propeller and motor

Servo motors for the ailerons and rudder

Stay tuned next week as we prepare the test the planes for flight and the kids try them outside!

3D printing and cars are all the rage. Imagine cars with custom body panels that you can swap out. This particular car is road-ready:

http://www.engadget.com/2015/07/08/local-motors-project-redacted-winner

Want to make your own 3D printed car model? Here’s how to build your own remote controlled car:

http://3dprint.com/49127/flutter-scout-3d-print-rc-car/

Until next week,

Tom