Hello everyone,

With mention of the 3D Lab in The Daily Record, radio advertisements, and public demonstrations, community members stop-by the lab each week. We are starting to have regular visitors to work on various projects. Younger members of the community take particular interest in the 3D printers and laser engraver. Thanks to donated materials by P. Graham Dunn, we teach them how to create custom laser engraver pieces to take-home, even during the first visit. Their excitement is wonderful to behold.

One such community member (an Orrville resident) is an avid bird watcher, brought his binoculars to the lab. Since he wears eyeglasses, the binoculars need refocused when viewing with or without eyeglasses. He designed a spacer (using AutoDesk’s free “123D” program) which clips together as two halves to form a ring. This way he can use the binoculars with or without glasses, without needing to refocus.

Producing the spacer normally cost $20 for one spacer by sending his CAD design to an online company to be 3D printed and mailed back. Our resin printer created the high level of precision that he needed in just an hour’s time. Now he can improve the design, print, and receive immediate feedback for future iterations. Many thanks to the Romich Foundation for making this possible.

The ceiling air ducts in our Word Processing Department disperse air in all directions. This can be inconvenient if air blows directly on someone at a desk. To avoid this, the personnel have several adjustable air directors that magnetically attach to the ducts. These directors are old and hard-to-find, so the maintenance department asked if we could design additional air directors.

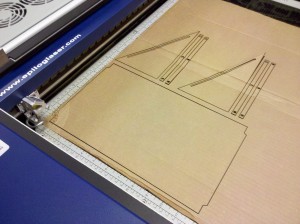

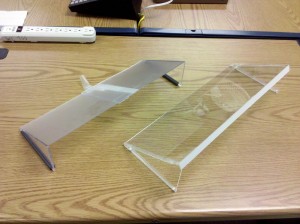

We used Corel DRAW to design the air director which is a simple-to-use “vector art” drawing program. The prototype design was laser cut onto cardboard to see how the pieces fit together and onto the air duct. Once the design was finalized, the final director was laser cut onto acrylic (generously donated by Wooster Glass and Jay’s Glass). The result was beautiful!

Instead of a magnetic attachment method, we chose a simpler “slide-on” mechanism. We can now mass produce air directors if faculty/staff around the college need them. Thanks to the Romich Foundation for the laser engraver/cutter; it made this project possible.

Last week was an important time for the Orrville Area Boys and Girls Club summer camp. The planes were assembled then taken outdoors for their first test flights. These are planes that kids built themselves using the laser cutter, 3D printers, and vinyl cutter. Instructors Chris and Nathan invited community members to help participants with the build process. It was truly a team effort and a wonderful success.

Chris mounts motor into plane chassis

Nathan tests motor electronics

Last-minute calibration

The first plane launch

Kids tandem flying their planes

Happy campers!

The kids did amazingly well flying their planes. The week before, they practiced on a virtual flight simulator using real controllers connected via USB. That way during flight outside they were used to handling the controllers. Chris and Nathan connected their controllers as “secondary” or “tandem”, ready to stabilize out-of-control planes to prevent crashing. The summer camp was a success!

Community members create interesting ideas in the 3D Lab. See how one member 3D printed a frame for his micro quad copter to prevent damage during flight. We like all things Star Wars. 🙂

Speaking of binoculars and seeing things up-close, see how a cell phone attached to a 3D printed frame creates a powerful telescope:

http://www.engadget.com/2014/10/09/ultrascope-space-nokia-lumia-1020

3D printing has important applications for the visually impaired, such as this art exhibition in Madrid:

http://www.openculture.com/2015/03/prado-creates-first-art-exhibition-for-visually-impaired.html

Until next week,

Tom