Hello everyone,

We have a lot to do in the 3D Lab to prepare for the Fall semester of activities and classes. In the works are designing a brochure and business cards to promote the makerspace when interacting with the public, creating maintenance schedules for the various equipment, and the installation of two new forthcoming 3D printers funded by the Wayne County Community Foundation. Anthony, our summer student assistant, has been wonderful by helping community members and working on lab projects.

One of our community members is an avid photographer, designing improvements to his cameras and other optical devices in CAD, then reproducing parts on our high resolution resin 3D printer. His latest design is replacement lens cap. The original is made from rubber, though the strap was damaged. The replacement cap was printed using special “flexible resin”. While the printer produced an accurate part, the resin was not flexible enough for repeated bendings. We hope to try the lens cap on our new “Taz 5” 3D printers that support truly flexible rubber later this summer. It was an excellent first attempt, though!

Removing the lens cover from the printer build plate

A nearly perfect replica using AutoDesk’s 123D Make program (free CAD software)

Yesterday, community members from the Orrville Area Boys and Girls Club arrived to learn vector art software and use the laser engraver. The goal involved engraving inexpensive drinking glasses provided by their club, courtesy of Kevin Platz. We taught the youngsters how to download images then manipulate them with Corel DRAW, create text and add special effects, then send these designs to the engraver. The Romich Foundation furnished a special rotary device that slowly spins the glass while engraving, allowing designs to be engraved around the entire glass. The kids had a lot of fun and created something truly unique in the process!

Glass sitting on rotary attachment, being engraved

Removing glass with both hands. 🙂

Everyone proud of their accomplishments

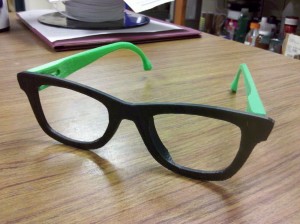

Speaking of the resin printer, we are experimenting with various methods of using it. There are limited styles of resin fluid available, namely black, white, gray, and clear. With the printer’s high level of detail, a community member wants to create eyeglass frames for his daughter using clear resin mixed with a third-party colored pigment. We are certainly willing to give it a try. The below glasses were printed with a traditional 3D printer; we are excited to see how the resin printer will handle the job. Stay tuned!

We are very thankful that P. Graham Dunn furnishes materials for students and community members while learning to use the laser engraver. The material has been a source of much excitement and creativity, a good way to get people interested in the 3D Lab and subsequently other equipment therein. One community member created this beautiful plaque, her first experience with the engraver. Thanks, P. Graham!

Stay tuned for more activities in the 3D Lab next week!

3D printers are now making pills! See how they can be made cheaper, on-demand, and exactly with the correct dosage.

http://www.bbc.com/news/technology-33772692

Can’t tell if that galllon of milk is near spoiling? 3D printed bottle caps can tell you ahead of time:

http://www.engadget.com/2015/07/22/3d-printed-bottle-caps-will-let-you-know-if-your-milk-goes-bad

Until next week,

Tom