Hello everyone,

With two weeks of summer remaining before the start of fall classes, we are cleaning and preparing the 3D Lab for another busy semester. The pending arrival of two additional 3D printers (courtesy of the Wayne County Community Foundation) will help with the print load as our existing three printers were frequently running simultaneously last semester.

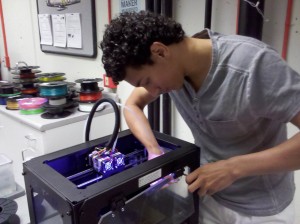

3D printers can and do cause problems on a regular basis, requiring maintenance and repair. Our first 3D printer, the Makerbot Replicator 2X, developed jammed filament in its extruder head, requiring replacement. The company shipped two extruder blocks and a replacement fan; Anthony accepted the challenge to install them. Even fixing 3D printers is a learning experience for budding engineers.

A few weeks ago, Sarah Jane and I visited Wooster High School to deliver two presentations on 3D printing and careers in engineering. Well over 60 kids from the Wooster Boys and Girls Club were excited to see how 3D printers work. With the portable printer temporarily out of filament, we brought the oversized Makerbot Replicator Fifth Generation. At this age group, PowerPoint slides were thrown out the window, relying on question and answer sessions instead. And there were many questions! Many thanks to Caitlin Petit for inviting us.

Back at the home front, we are still learning the ins and outs of the high resolution resin 3D printer. It is a costly printer to operate (about 6-8 times more cost in consumables than plastic 3D printers), so we look to cut costs wherever we can.

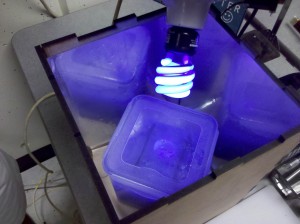

We go through a lot of isopropyl alcohol to rinse parts after being freshly printed. The alcohol becomes dirty with liquid resin. Instead of disposing the used alcohol, Anthony had an ingenuous idea; place the entire alcohol tank in the ultra violet light box! The light eventually cured the suspended resin, causing it to congeal and fall to the tank’s floor. This gelatinous resin is scooped out, leaving somewhat clear and usable alcohol behind. Good job, Anthony!

Resin-infused isopropyl alcohol

Tank exposed to ultraviolet light

Mostly clean alcohol again!

Community members and students use the lab’s laser engraver on an almost daily basis. See how one person made a beautiful plaque, courtesy of P. Graham Dunn for the material. With the image being engraved, the laser can either draw the image with many dots from top to bottom (like a laser printer) or draw low powered lines and curves (like a plotter). The latter method is much faster to engrave. It is wonderful to see creative works made with this machine.

See how a 3D printed stethoscope costing 30 cents outperforms its traditional $200 counterpart:

3D printers are making inroads into organic printing, namely human tissue. See how printers produce small tumors that can be tested with various cancer treatments (thanks for the link, Jane!):

Until next week,

Tom