Hello everyone,

With the start of Fall semester next week, the busy 3D Lab is about to become a lot busier. Engineering classes building LEGO Mindstorms controlled robots will use the lab to augment their designs, perform material stress tests, and more. Our multi-material 3D printers have yet to arrive; students will put them to good use later this semester.

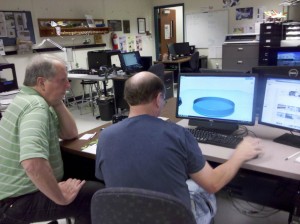

New students visited the 3D lab over the summer to use the equipment and 3D print their CAD designs. Various members of the community work on projects here as well. One of these people is an avid bird watcher. He uses AutoDesk’s free 123D Make program to design replacement lens covers and other apparatuses for his cameras and binoculars. Another community member caught wind of this, so now they are working together to repair each other’s equipment. It’s a wonderful form of community.

CAD design lessons

3D printed lens cap is the gray one

The 3D Lab made another road trip, this time to the Holmes County Fair! We setup a table with the portable 3D printer, had plenty of objects to pass around, and even made keychains with the laser engraver to promote the Holmes Campus. The 3D printer was a big hit; I talked continuously for three hours to fairgoers of all ages. We 3D printed numerous objects during the fair; kids were especially fascinated by this.

John Lorson, coordinator of the Holmes Campus, was sadly bitten by the 3D bug. Not only did he learn how to operate the portable printer, but he ran the 3D table for the rest of the week! The said the printer drew seven times more people to the Wayne College table than in past years at the fair. What a good way to promote the college and spark interest in engineering and invention at the same time!

Back at the home front, our newest 3D printer (the Makerbot Replicator 5th Generation, courtesy of the Romich Foundation) was having problems. A ribbon cable connects to the extruder print head to control the heat, monitor temperature, etc. A design flaw in the printer’s enclosure was mangling the cable, catching on a plastic tab in the back of the printer. Thanks to the service plan that we subscribed to, the company quickly sent a replacement cable, free of charge. And now the printer is back in business!

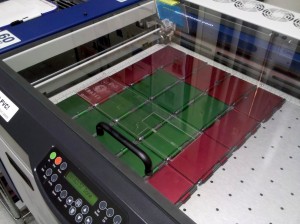

Last but not least, one of our staff members learned how to use the laser engraver to create notepads for vacation bible school (courtesy of P. Graham Dunn). Engravers are perfect for mass producing items because multiple items can be placed on the engraving bed. In the photo below, Chad used clear acrylic (courtesy of Wooster Glass Company and Jay’s Glass) to test-engrave a notepad to check for artwork placement without wasting notepads in the process. He’s an expert engraver now, a new skill that he developed from the 3D Lab!

The 3D printed OctaWorm robot can go where no other robot can (designed by UA student Juan Cristobal Zagal):

http://3dprint.com/88873/3d-printed-octaworm-robot

See how this NASA robot will build big composite rocket parts:

Until next week,

Tom