Hello everyone,

With the first week of the Fall semester at its end, the 3D Lab proves a busy place for students and community members. We are interested to see what the engineering classes will cook-up in the lab for projects. The lab is also used as a hang-out place for students to socialize, do homework, and help each other create cool things with the equipment. The Wayne College R/C Flight Club had their first meeting there on Monday evening; be sure to stop by the next Monday at 6:00 if you are interested in joining!

As introduced in a previous post, did you know that the 3D Lab is involved with a joint research project with the University of Chile? Jeff Davis and Dr. Dan Deckler from the University of Akron and Juan Cristobal Zagal from the University of Chile are building a “snakebot” that can squeeze itself into the gaps, crevices, and cracks of piles of rubble. A robot that can shift its actual size, expanding when it needs to, and constricting when things get tight.

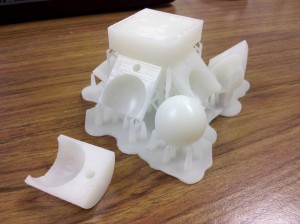

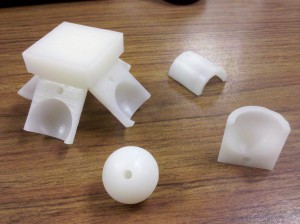

Parts of this OctaWorm require tight tolerances, finer than what traditional 3D printers can accomplish. Thanks to the Romich Foundation, we produced robot parts with our resin 3D printer. The results were night and day. The cost of producing resin parts is 6-8 more expensive than plastic based 3D printing, but definitely worth the cost for certain scenarios.

Robot parts printed on a mesh of “supports” which keeps them from moving around during printing

Final robot parts with supports removed

The 3D Lab is proud to be involved with this project. We’ll keep you posted as we learn more of the OctaWorm’s development.

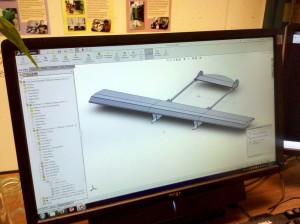

Speaking of the R/C Flight Club, members are already full-tilt designing and building new planes. The laser engraver is typically used to cut the foam board wings and bodies while motor mounts and aileron linkages are 3D printed.

Chris (president of the club) is learning how to use SolidWorks to create plane designs. The program has a “metal folding feature” that allows flat designs to be folded and shaped in 3D, similar to what a metal bending machine would do during actual fabrication. He is getting quite good at it with this glider that he invented:

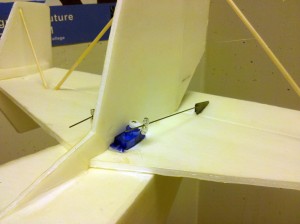

Nathan has built his largest R/C airplane yet, a dual propellor monstrosity an that actually lift itself vertically and hover. Our laser engraver is not large enough to cut the wings and body parts that he needed, so Nathan resorted to manual cutting methods (craft knife and/or hot knife). The plane is amazing and flies quite well for its size!

Ready to fly

Huge propellers and 3D printed motor mount

3D printed linkages

A couple of weeks ago, representatives from Heartland Point in Orrville visited the lab to discuss future collaborative works. Our former marketing person was there (Cindy Summers); it was wonderful to see her involved with this project. Wayne College plans to offer a three day workday on CAD design and 3D printing, hosted at Heartland Point and at the 3D Lab.

Tom explaining 3D printing

Kenny (one of our students) explains laser engraving

Stay tuned as we work-out the details of this free offering to the public.

As mentioned above, the 3D printed OctaWorm robot can go where no other robot can:

http://3dprint.com/88873/3d-printed-octaworm-robot

MIT develops a 3D printer that extrudes molten glass:

http://www.gizmag.com/3d-printer-glass-objects/39137

Until next week,

Tom

![image[1]](http://blogs.uakron.edu/waynec3/wp-content/uploads/sites/1058/2015/09/image1-300x225.jpg)