Hello everyone,

Exciting things are preparing to happen in the 3D Lab. Now into the third week of the semester, engineering students will soon begin robotic designs that will use 3D printing for some of its parts. These robots have specific tasks to perform such as throwing a weighted ball a calculated distance, locating and capturing an object in a confined area, and more. The creative robotic designs never cease to amaze us.

Later this week, we will receive two additions to the 3D Lab, matching Taz 5 3D printers! These highly rated machines were provided by the Carl E. Congdon, Jr. and Susanna Congdon McIntyre Memorial Fund, a component of the Wayne County Community Foundation. The printers will create 150% larger objects than our other printers, using exotic materials such as rubber, nylon, t-glase, HIPS plastic, and stone- & wood-infused plastic. Needless to say, we are quite excited! More news as we dig into these marvels next week.

As mentioned earlier this year, the summer flight camp with the Orrville Area Boys and Girls Club was a wonderful success. We posted its progress throughout the summer; please read previous blog entries here for details. Instructor Chris made a nice video to recap the activity, a testament to the fun time the kids had while learning makerspace technology to build the planes. Please click the picture below to watch the video.

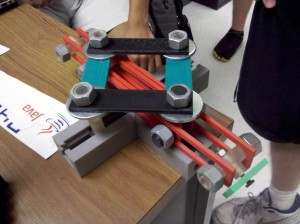

Back in the 3D Lab, a UA graduate student is building a device that will test the structural integrity of synthetic organ material, such as a synthetic heart. The device stretches the material in four directions at the same time, yet individually controllable. His invention uses a combination of ABS and PLA plastic. Detailed parts (such as threaded sockets) were created with the high resolution resin printer. We are quite impressed with his design and the initial prototype seems to work well!

We continue to be amazed with projects that students and staff dream-up with the laser cutter. Staff member Theresa wanted to create award medals for the local live drama theater. Thanks to generous donations from P. Graham Dunn, she learned how to use the laser cutter for the first time. The medal’s shape and fancy outlines were laser cut while text was engraved on top. We used two passes of the laser to “burn” the wood more thoroughly, allowing for better contrast. Theresa was quite pleased with the result!

If you would like to create giveaway items, awards, and gifts, we are welcome to teach you how to use the laser engraver. It’s quite easy and addicting. Once you start creating things, you will have all sorts of new ideas to try. Please stop-by A-121 to browse our selection of free items to engrave.

See how 3D printing enables a UA professor of polymer science and biomedical engineering to develop 3D printed biodegradable polymer scaffolds, the frameworks within which bone will grow, with the hope of changing the face of craniofacial reconstruction.

For the first time, a patient receives a 3D-printed titanium sternum and rib cage:

http://www.gizmag.com/3d-printed-sternum-and-rib-cage-csiro/39369

Until next week,

Tom