Hello everyone,

It’s amazing how far we have come since the 3D Lab’s opening in January 2014. Looking back, we’ve collaborated with 18 community organizations, a dozen businesses, and another dozen schools. We’ve made over 20 visits to these locations to demonstrate 3D printing, using the portable 3D printer provided by the Romich Foundation. Our impact to the community is substantial, a testament of the need for polytechnic skills to be introduced to all generations.

A case in-point, an employee of Orrville City Schools brought his son and friend to the 3D Lab for a laser cutting and engraving project. They wanted to construction a “suggestions box” made from plywood. They entered the desired box dimensions and wood thickness into www.makercase.com which provided laser-cut ready files. The box sides are cut “dovetailed” to be easily glued together. It was wonderful to see young people learn this advanced technology for the first time (and so easily they mastered it)!

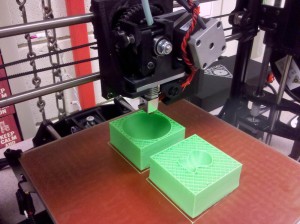

Wayne College engineering students are busily building different LEGO Mindstorms robots every two weeks to perform various tasks. These robot toss a ball, locate and drive to colored markers, push each other off platforms, and more. The lab’s 3D printers are put to heavy use, creating many 3” cubes with hollowed insides. This produces different weights depending upon the internal cavity shape. Students then use MatLab to mathematically determine how much motor power is need to toss the cube a set distance. Stay tuned as we report of the success of the block toss results!

3D printer creating boxes with custom cavities

Finished boxes of varying weights

In-progress robot construction

If you remember last month, Andrew from the Technical Support Services department designed an instantly useful bookbag hanger for desks. He is at it again, this time with a coin organizer for desk drawers. It not only stacks coins of similar value, but allows easy dispensing from the bottom of the stack. It works very well and fits our desk drawers perfectly. Thanks, Andrew! If you would like a dispenser, please let us know.

The 3D Lab’s laser engraver (generously provided by the Romich Foundation) is frequently used for interesting projects. An adventurous student learned how to engrave the back of his iPhone with excellent results. Thankfully the laser did not cut the phone in half instead. 🙂 His latest creation is artwork for his laptop. The cover is anodized aluminum, perfect for engraving. The laser burns away the painted coating, revealing the white metal beneath. As you can see, the result is beautiful!

We have lots more to report in the 3D Lab; stay tuned next week.

Now that the International Space Station has a 3D printer, why not create “pods” that grow food in space? The AstroGro system does just that:

http://www.gizmag.com/astrogro-plant-garden-space/37167

See how NASA uses 3D printing to create a high-performance “astro pump” (90,000 revolutions per minute) that uses 45% fewer parts than traditional pumps:

http://www.gizmag.com/nasa-tests-3d-printed-turbopump/39139

Until next week,

Tom