Hello everyone,

With the first week of the semester at an end, new faces are showing up in the 3D Lab, students interested in making new friends and exploring what the room has to offer. Flight Club president Chris Ryan is also with us semester with big plans for the club. Members are focusing on building/flying drones this time, with innovative ideas that will be revealed soon. Meetings are Monday evenings at 6:00, if you are interested. By next week, the Electronics Station should be ready for use. We are excited to see what students will build and invent this semester; there is rarely a dull moment in the lab.

We are thankful to the community who support the mission of the 3D Lab. It is through your generous funding that the 3D Lab is accessible and freely available to students and the community, encouraging them to dream and build. We particularly thank the Willard E. Smucker Foundation for providing this support.

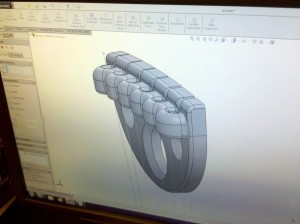

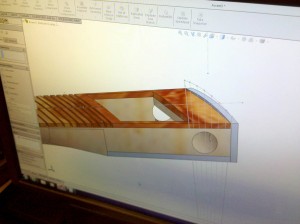

Last semester, one of our engineering students decided to build an electric guitar using SolidWorks, a sophisticated CAD program used in our engineering classes. He intends to fabricate his design with the laser cutter, 3D printers, and an offsite CNC machine for the various components. The guitar will have some innovative features such as bridge that is located in the middle of the guitar, not the end. It will be interesting to see it being made and eventually played!

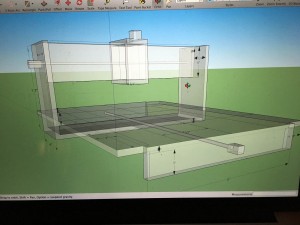

Speaking of inventions, Ben is making progress on his home-built CNC machine. His goal is to build this machine using only $100 worth of parts. He is collaborating with community members Barry Romich and Mike Sciarini for mechanical, electrical, and engineering advice, especially with the bearing system that moves the gantry along three axis. He created a sketch of the overall design with CAD which helps with material planning and assembly:

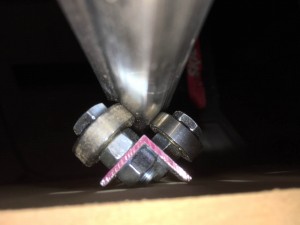

The rods that move the gantry travel along bearings that are quite ingenious in-design. They keep the rods in perfect alignment (note the two wheels positioned in a “v” shape) while providing smooth travel.

We will soon provide a video of gantry movement in-action. It’s amazing that Ben is building a CNC machine in his garage from basically printer parts, MDF board, a Dremel tool, and a low-cost Arduino microcontroller!

The Shantz Organ Company hosted their second Open House last Saturday to promote their makerspace, an important initiative in Wayne County. The event was well attended by many members of the community. Wayne College supported the event by demonstrating 3D printing and its role in supporting the Shantz initiative and the makerspace ecosystem developing in surrounding counties. Also present was a representative from C.H.A.M.P., an amazing makerspace in the Canton area. They build their own 3D printers from scratch, which is amazing!

People are always interested in 3D printing technology. Back in the days of dot matrix printers, the introduction of the laser printer really shook the world, a revolution in consumer printing. The 3D printer is poised to repeat history again.

To introduce folks to what is possible with the fabrication equipment at Shantz Organ, the company is soon offering workshops on woodworking (with CNC machines), metal working, and laser engraving. With each workshop, partipants will build something fun and useful. More details coming soon.

Back at the 3D Lab, Nathan used our large-format Taz printers to build a full-size mask from a popular videogame. Sections were individually printed then glued together. Nathan plans to sand the mask smooth, then paint it. It will be interesting to see the final result, even more interesting if he is brave enough to wear it. 🙂 Good work, Nathan!

Given that a 3D printer is already on the Internatioanl Station Station, what would it be like to use 3D printers on the moon?

http://hackaday.com/2016/01/03/32c3-3d-printing-on-the-moon

See how 3D printers are making components for NASA scramjets, such as this hypersonic engine combustor:

http://www.gizmag.com/atk-orbital-hypersonic-3d-printed/41427

Until next week,

Tom