The second week of the semester has finished. Engineering students in the Dynamics class (for model rockets and more) do not yet have assignments that involve the 3D Lab. But the room is a flurry of activity with students working on their own projects. There is rarely a dull moment.

For instance, last semester one of our students started designing a custom guitar using Solidworks, a computer aided design (CAD) program. It will be fabricated using the laser cutter and 3D printers. It’s quite an original design, too. That project is still underway, but he has a new project; a two-wheeled skateboard! Using the drill press, he fabricated metal mounts for the small wheels, then mounted them on either end of the skateboard.

With the first build, he realized that the wheels are too close to the board, making it difficult to angle it while riding. His next idea involves fabricating custom wheel mounts using the resin 3D printer (generously provided by the Romich Foundation). This printer supports “castable resin” that will form the mounts (that will be cast from metal). Stay tuned as we embark on this exciting project.

The R/C Flight Club is really taking off this semester (pun intended). Quad-copters are all the rage; students are flying palm size machines, larger quad-copters, and a really large tri-copter. Some of these were built from kits. The club’s goal is assembling enough copters to race them later this semester. Chris, the club’s president, mounted a camera on his copter, then taped a video screen onto a blacked out helmet. The result is a virtual reality-like experience when flying the copter. Quite inventive!

One doesn’t need to be an engineer nor CAD designer to make wonderful things in the 3D Lab. Jackie, one of our staff, used the vinyl cutter and heat press to create a personalized t-shirt for a retiree. These machines are provided by the Orrville Area Boys and Girls Club where its young patrons visit the college to use the technology, too.

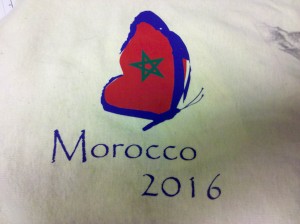

Most interesting is Paul’s project, a faculty member who is creating t-shirts to promote an upcoming travel experience to Morocco. His design uses three vinyl colors that are individually cut and arranged. It’s quite a challenge, but quite beautiful! We are thankful for OABGC for providing this equipment.

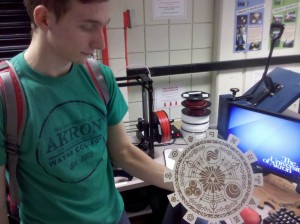

Last but not least, Nathan laser engraved this beautiful wooden disc (material generously furnished P. Graham Dunn). After engraving the pattern, he used a wood carving CNC machine at a friend’s house to cut the gear’s teeth around the edge. His final step will be painting the disc with glow-in-the-dark paint. Quite ambitious!

Learn to play the violin with this free-to-download model (and it actually sounds good!):

http://hackaday.com/2016/01/02/the-hovalin-open-source-3d-printed-violin-sounds-great

Have aching feet? Here’s how you can use your smartphone to design custom-fit 3D printed insoles:

http://www.gizmag.com/wiivv-3d-printed-insoles/41236

Until next week,

Tom