Hello everyone

The 3D Lab has been quite busy lately. In a week’s time, we made a road trip to Alliance, taught a 3D design and printing workshop in the lab for The Schantz Organ Company, promoted engineering at the Wayne College annual Milkshakes & Majors event, and provided lab tours for faculty. And that’s not including the crazy projects that students are working on. The lab is a non-stop room, full of creative minds with machines to turn ideas into reality.

One of our students is an avid skateboarder and uses the 3D Lab to create original inventions, notably a two-wheel skateboard that feels like a wooden hover board when riding it. The low wheels are held in-place by a metal mount that he fabricated with the lab’s drill press and other tools, the wheel covers are 3D printed, and the overall design was drawn-up with Solidworks. Check-out this fun video of the mount being made and tested:

Heavy skateboarding sometimes damages the ends of the board; the wooden ends break-off over time. His current project involves detachable ends that can be replaced as needed. The prototype is 3D printed, while the final result will be professionally fabricated with tougher material. Also notice the t-shirt; it was made in the 3D Lab as well!

Ben is making fabulous progress on his homemade CNC machine. It can now draw designs with an attached pencil and carve designs on (and through) wood! The machine uses an Arduino microcontroller to control the 2.5A motors for the X/Y/Z axis, which in-turn are powered by a relay board attached to the Arduino. Designs are loaded onto an Apple laptop running free CNC software (Easel by Shapeoko), then sent to the CNC machine. Ben’s current project is building a dust collection unit for the router head, as the machine makes a lot of sawdust during the carving/cutting process.

CNC machine with microcontroller on table

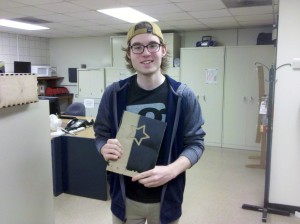

Ben with a carved star

Computer controled pencil drawing

A CNC milled guitar body!

Here is a video of it in-action. We’ll keep you posted as he finishes this project. He’s making excellent progress but still has a lot to do.

Last week, the 3D Lab made a road trip to demonstrate 3D printing for the Alliance Amateur Radio Club. The group has been around since 1950, a friendly group of men & women who are bound together by their interest in amateur radio. Amazingly, these groups are everywhere.

These folks are naturally inclined tinkerers, so were quite eager to learn about 3D printing and the lab’s availability to realize ideas and fabricate radio parts at Wayne College. During the presentation, we printed a morse code encoding key (also called a “straight key”) using the portable 3D printer provided by the Romich Foundation. The presentation was well received and went well beyond their scheduled meeting time.

The Wayne College 3D Lab is willing to present 3D printing and discuss careers in engineering to schools, organizations, and businesses. Please contact us at tjh1@uakron.edu to schedule a visit!

Think that 3D printers can only build three dimensional objects? See how this person modified his printer to etch circuit boards:

http://hackaday.com/2016/03/03/etching-pcbs-with-a-3d-printer-2

This printer goes one step further and places electronics within the objects it creates:

http://www.gizmag.com/ir3-3d-printer-electronic-componenst/36966

Until next week,

Tom