Hello everyone,

With Finals Week approaching in two weeks, students work on final projects for various classes. Engineering students in particular are finalizing their model rocket designs, some of them made on 3D printers. The official Launch Day is Wednesday, April 27th at 9:15 a.m. (barring inclement weather). If you have time in your schedule, stop-by our soccer field that morning to see rockets launch, made from wood to metal to plastic!

Ben makes amazing progress with his home-built CNC machine. The entire project comprises of donated and purchased parts, totaling a mere $200. A few weeks ago, he invited a small group to his garage to demonstrate the machine. The CNC uses off-the-shelf components such as a router, drawer sliders, angle iron, etc. An Arduino microcontroller drives three heavy-duty stepper motors to move the router and various parts were 3D printed, too. It works beautifully!

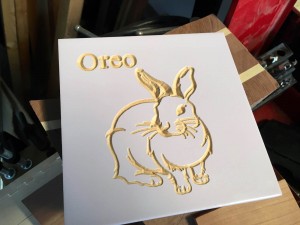

Ben’s latest accomplishment involves using a “v-bit” (donated by the Romich Foundation) instead of a regular routing bit to cut prism-like designs into wood. The trick is finding free software to vary the bit’s cutting depth. Since his sister’s rabbit was having its third birthday, Ben created a plaque to celebrate it, using donated wood from P. Graham Dunn:

Over the past couple of weeks, I had the pleasure of visiting the Wayne County Schools Career Center in Smithville, Ohio, a member of the Route 30 Corridor Makerspace Ecosystem. At WCSCC, students learn to fabricate using high-end equipment such as industrial milling machines, metalwork, electronics, power line technology, house building, and so much more. If you haven’t been to the Career Center in a while, make it a point to take a tour!

Machining shop

House building shop

Metalwork and welding shop

The Ecosystem group tours and networks area businesses, schools, and organizations, including Stark Tech, Wayne County Schools Career Center, The University of Akron Wayne College, and many others. The goal of this effort is to support each other in this era of digital fabrication which revolutionizes how things are made and who can make them. If you or your organization wishes to be involved with this initiative, please contact Victor Schantz at v.schantz@schantzorgan.com.

Back at the college, one of our tried-and-true Taz 3D printers finally malfunctioned after a ton of heavy use. The printer would not allow filament to travel into the printer head, a classic “jammed extruder” problem. The following top-down photo shows white filament stuck inside the extruder assembly:

When filament is heated too long without movement, it can carbonize inside the nozzle, permanently clogging it. But with our problem, a broken piece of filament jammed in the heat chamber -before- reaching the nozzle. Furthermore, we were using HIPS plastic which does not carbonize as quickly.

After scouring the Internet and a call to Taz technical support, we learned to remove the nozzle, insert a 2mm Allen wrench into the heated chamber to dislodge the plastic. To ensure a clean chamber, we used a flashlight on one end and a front-facing smartphone camera on the other end to ensure a clear path:

The Taz 3D printers are known for being well engineered and easy to repair. When printers fail, our students are willing and eager to fix them! We are thankful for their enthusiasm and the generosity of the Wayne County Community Foundation for providing these machines.

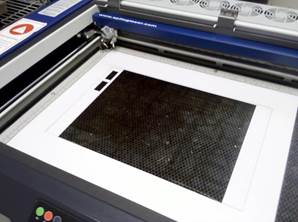

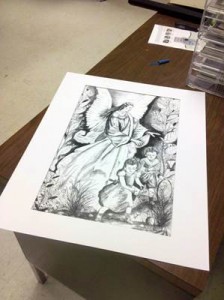

Lastly, a community member asked if she could use the laser engraver (provided by the Romich Foundation) to cut matting for artwork that she wants to frame. We taught her how to use Corel DRAW to design the cutting pattern, then how to configure the laser to cut safely through the matting material without burning it. The result came-out beautifully!

Stay tuned next week as we report the success of Launch Day for our engineering students’ model rockets and other happenings in the 3D Lab.

Read about the world’s largest commercial aircraft engine being fired up for the first time, with some of its parts 3D printed:

http://www.gizmag.com/ge9x-largest-engine-testing/42880

See how Boeing proposes 3D printing -ice- for aircraft certification:

http://www.gizmag.com/boeing-3d-printing-ice-certification/42850

Looking for an interesting project that combines robotics, 3D printing, and electronics? This low-cost, make-it-yourself, line-following robot is for you:

http://www.instructables.com/id/Low-Cost-Arduino-Compatible-Drawing-Robot

Until next week,

Tom