Hello everyone,

Summer break is finally here. With students rushing about the halls and studying hurriedly last week, it seems like a quieter, different world this week. Students and community members still come to the Wayne College 3D Lab to finish-up personal projects, though.

One exciting announcement is that we now support printing with rubber! 3D printers typically build objects out of plastic, so this is major news. Our Taz 5 printers (generously provided by the Wayne County Community Foundation) supports this upgrade. Our students are really excited about this; now they can print plastic parts with rubber bumpers, wheels with rubber treads, gaskets, and so much more.

Nathan, our resident 3D Lab staff and 3D printing expert, upgraded the Taz printer, replacing the plastic extruder with a two-extruder assembly that supports plastic and rubber extrusion during the same print job. It is so nice to have student engineers around; they know almost everything and dig right into complicated projects. Or perhaps I am simply lazy. 🙂

The rubber extruder uses NinjaFlex material. This is incredible flexible and strong rubber; it’s almost impossible to tear it apart nor separate layers that have been printed. There are also different densities available, from very flexible rubber to “wheel chock” semi-rigid material.

One object that we recently printed is a rubber sleeve to fix a paper “stamp” used by crafters. The stamp’s plastic casing was cracking apart, so the non-slip rubber sleeve protects it from damage and makes the stamper usable again:

Jonathan from the UA Human Powered Vehicle Team visited the 3D Lab last week to create car decals for an race in Athens, Ohio that happened this past weekend. He was already familiar with the Roland vinyl cutter (provided by the Orrville Area Boys and Girls Club), as this brand is used in professional shops all over he world.

Thanks to the car’s beautiful decals, it won first place! Seriously, though, the team’s vehicle won 1st place Overall, 1st place in Innovation, 1st place in Endurance, 1st place at Women’s drag racing, 2nd place at Men’s drag racing, and 5th place in Design. Congratulations! You can follow the team on Facebook at https://www.facebook.com/AkronU.HPV

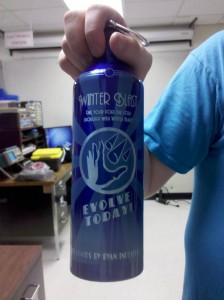

Students, faculty, and staff are having a wonderful time learning the laser engraver lately due to beautiful water bottles provided by P. Graham Dunn. Folks who stood on the fence from visiting the 3D Lab are now excited to engrave their own bottles and see what the lab is all about.

Printing round objects requires a special rotating device, ours generously donated by the Romich Foundation. This allows the laser to engrave on all 360 degrees of the bottle. Below, Leslie creates a design in Corel DRAW that similates a bottle that has been “flattened”:

A bottle is then placed on the rotator inside the engraver, which slowly spins the bottle as it engraves. It is magical to watch.

Our students have been creating some interesting designs, though designs that I cannot recognize because I’m from an older generation. 🙂 But watching their enthusiasm is rewarding!

To celebrate the end of the semester and another exciting time at the Wayne College 3D Lab, a number of students brought musical instruments for a jamming session. The group picked tunes and followed each other while busy 3D printers made their own “music” in the background.

As students take a break this summer, we will all have fond memories of working together and learning from each other in the lab. Many are returning to Wayne this fall, so the 3D Lab “family” will be back for more interesting projects soon!

See how 3D-printed hair leads to fuzzy machines and sticky blocks:

http://www.engadget.com/2016/05/16/3d-printed-hair-finds-practical-uses

See how lab-grown blood vessels appear a safe alternative to synthetic implants:

http://www.gizmag.com/bioengineered-blood-vessel-tests/43330/

Until next week,

Tom