Hello everyone,

Things have been hopping at Wayne College since the start of classes almost three weeks ago. There are lots of new faces as students roam the halls, others from Fall semester resume their classes and continue friendships once again. The 3D Lab was crazy busy the week before Christmas; each day was packed with community members and students making personalized gifts. The start of semester is no different; students already made the lab their “hangout place” each day, while engineering students are already 3D printing parts for school projects.

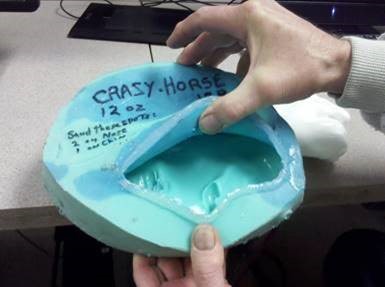

We had the pleasure of working with community member Tad, an accomplished sculptor. One of his specialties is creating realistic faces of Indians that are compressed when looking front-on, yet full sized when viewed from the side. This allows the faces to be mounted on plaques, yet still be three dimensional.

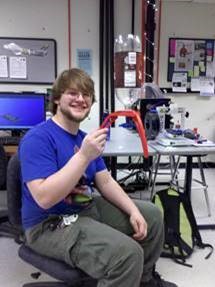

Tad wanted to make a plaque with opposing faces of the same model. We had just the right tools for the job. He learned how to use the 3D scanner to create a computerized “mesh” model of the sculpture. This was loaded into the 3D printer software and “mirrored” before printing. It took about 10-12 hours for a complete reproduction! All of this technology was new to Tad, but he fastidiously figured it out with help from 3D Lab staff.

Tad used epoxy to coat the printed face, smoothing the lines or “layers” introduced by 3D printing. Finer detail (such as hair strands) was lost from the scanning process, so he carved fresh detail into the 3D printed model. After that, he created a rubbery mold so the face could be mass produced.

When he poured his first mold for a finished face, the result was impressive, even from using a 3D printed master. Tad is also an accomplished painter, so after careful painting, adding some turkey feathers and an eyeball (who doesn’t have an eyeball rolling around?), the finished product was amazing.

This process sounds easy, but it took a number of attempts with the 3D scanner, printer, determination, and patience to work-out problems. Tad was with us for several weeks to see the project to completion. But the end result was certainly worth it!

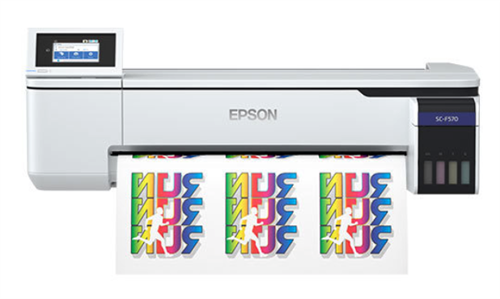

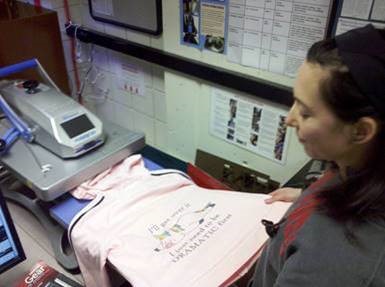

Last semester, the Charles E. Loehr Charitable Trust provided funds to upgrade our heat press to a model that supports making things with the dye sublimation process. This involves printing designs to a “dye sub” printer with special ink & paper, allowing full-color images to be heat pressed onto a variety of surfaces, notably textiles.

Earlier this season, a community member wanted to make a birthday gift for her daughter, notably custom hoodies with a special message and a unicorn! The process was easy. The graphics and lettering was printed from Microsoft Word to the dye sub printer. These needed to be “reversed” before printing, as they will become “unreversed” after transferring its image with the heat press. Special care was needed using the hoodie in the press; the plastic zipper had a tendency to melt! We used a special “pillow” to allow the zipper to sink into it, avoiding the direct heat & pressure. The result was quite nice!

Once a year, the Baden Powell Institute hosts an event at the Dalton Local Elementary & Middle School designed to give Scout Leaders an in-depth look at a variety of topics that are not covered in their Formal Leader Training. Several hundred leaders attend this event filled with training sessions and a couple dozen products & services vendors in Wayne & surrounding counties. The Wayne College 3D Lab has been proud to be part of this event the past couple of years (and this year’s event, too!).

3D printing is a hot topic for scouts in which the skill can be earned into a badge. For example, see how an Arizona Boy Scout troop is using a 3D printer to create prosthetic hands for those in need:

https://www.nbcnews.com/video/boy-scouts-make-prosthetic-hands-with-3d-printers-625160259719

The 3D Lab is open for students, faculty, staff, and community members alike. Feel free to stop-in! We have student staff who are happy help you learn how to 3D print, fix broken items, or create something new. Our hours of operation are posted here. Family members welcome to group tours, too.

Stay tuned next week as we introduce more interesting folks who participated in last year’s Maker Faire!