Hello everyone,

It’s been an exciting week in the 3D Lab. Even though the lab sees less use by students during the summer, our staff is making good use of the equipment. Various employees are learning the laser engraver which involves studying a safety guide, taking a written safety & use test, and demonstrating proper use. This technology is more approachable and easier to use than 3D printing; it allows people to become interested in making and inventing with basic computer skills.

Our summer camp is into its second week and is a big success. Last week, kids from the Orrville Area Boys and Girls Club joined instructors Chris & Nathan and the Wayne County RC Club in outdoor flying practice. This gets kids excited about their summer project, eventually building their own motorized airplanes using laser cutting, 3D printing, and vinyl cutting technologies. Needless to say, the kids were thrilled!

Chris and the others connected two controllers in tandem to allow kids to fly the planes, though the adults could regain control if the plane needed flight correction.

Chris introducing camp

Nathan tandem-flying plane with attendee

Community member explaining flight physics

Chris repairing a damaged plane

Stay tuned as we report camp progress throughout the summer!

A couple of weeks ago, the Ohio Higher Education Computing Council (OHECC) held its annual conference in Oxford, Ohio at Miami University. Numerous presentations were offered related to computing and technology in education. Representing the University of Akron Wayne College, I presented the history and advice on creating a successful makerspace in an academic environment. The presentation was well received, indicated by non-stop questions during and after the presentation. I also gave-away free UAWC3 branded notepads which helped with motivation, too. 🙂

If you wish to see the slides for this presentation, please click here

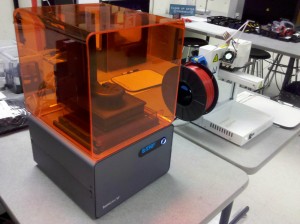

Last but not least, the resin printer arrived today! Thanks to the generous support of the Romich Foundation, we now have a 3D printer that is capable of high resolution, high quality parts. It works by a laser shooting into liquid resin, solidifying each layer as the part is printed upside-down and slowly lifted out of the liquid. It is amazing to watch.

Our first print was a success. Below, note the part on the left printed on a typical 3D printer at 0.2mm per layer. The part on the right is from the resin printer at 0.1mm. The quality is amazing. The printer can print even finer parts at 0.025mm as well as rubber based resin for flexible parts. We are so thankful for this addition to the 3D Lab (and our students – notably Anthony – is excited about it, too).

Stay tuned as we discover more about this technology in the following weeks.

3D printing makes its way into large engineering efforts. See how a 3D printed steel pedestrian bridge will soon span an Amsterdam canal:

G.E. is getting into the game with its first full 3D printed jet engine:

http://www.gizmag.com/ge-fires-up-all-3d-printed-jet-einge/37448

Until next week,

Tom