Hello everyone,

It’s a quiet Friday at Wayne College, but not quiet at all in the 3D Lab. A half dozen or more students are doing homework and working on various projects, from automatic bicycle brake lights (powered by an Arduino microcontroller) to a bulldozer model complete with moving treads. The beauty of the 3D Lab is that half of the projects are related to classes, while the other half are projects that students are building and learning on their own steam. One of our students is excited to spend the entire Spring Break in the lab; what is wrong with him? 😉

The UA Zips Electric Racing team uses the 3D Lab to create custom parts for their upcoming car. The current project is a printed circuit board (PCB) enclosure. PCBs are used to control the dashboard lights and displays, motor controls, and braking/acceleration controls.

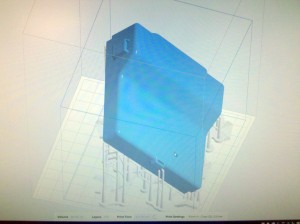

Trevin designed the enclosure cover with CAD software. This covered needed to be semi-transparent, so we fabricated it using the resin 3D printer (provided by the Romich Foundation).

The cover actually prints upside-down, as the printer slowly lifts the part out of a tray of liquid resin. The white “posts” in the photo are what holds the cover from falling into the tray.

The enclosure’s base was printed with our multi-material Taz 3D printer (courtesy of the Wayne County Community Foundation). HIPS plastic was chosen for its high strength, heat endurance, and easy-to-print material. The clear and blue printed parts are below, then shown assembled with the car’s wiring harness. Three enclosures will be produced to control the electric car’s major functions. Purchasing an enclosure would have been prohibitively expensive, so 3D printing was the perfect solution!

A couple of weeks ago, the 3D Lab made a road trip to Wadsworth Intermediate School to introduce 3D printing, real-world applications, and careers in engineering. We presented two presentations to 60 fifth-grade students, not an easy feat! The students were easy to talk to and full of questions. During the presentation, our portable 3D printer produced a “bear robot”, given that the school’s mascot is a grizzly. They were fascinated to watch the bear being created, like magic, before their eyes. Some commented that they want to be engineers when they finish school, others wanted a 3D printer for home. Their enthusiasm was contagious!

We are thankful to Wadsworth Intermediate School for hosting us and look forward to collaborative projects with Wayne College in the future.

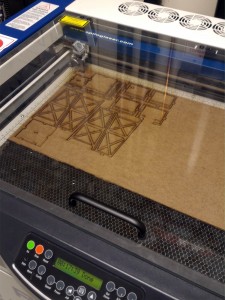

Tim, one of the many inspired students frequenting the lab, is an avid board gamer. Lately, he’s been using the laser engraver to create custom pieces for these games. Using Adobe Illustrator, he whipped out these sophisticated models in an evening. The pieces, after laser-cut, snap and glue together to form 3D models.

As you can see, the game pieces are amazing! Tim used 1/4″ (or thicker) MDF board to create the pieces from. The laser engraver had trouble fully cutting the designs, even after two passes of the beam. The third time was a charm, though. We found that changing the travel speed of the laser makes a big difference with cutting depth. Good work, Tim!

Stay tuned for news on more exciting projects in the 3D Lab next week!

It is commonly thought that 3D printers create toys and non-functional models. Not true! See how this person printed a working, tabletop jet engine:

http://hackaday.com/2016/02/15/a-3d-printed-jet-engine-appears-to-function

See how this 3D-printed UAV (unmanned aerial vehicle) can go from not existing to flying within 24 hours:

http://www.gizmag.com/3d-printed-uav-airframe/31473

Until next week,

Tom