Advanced fermentation technology for rhamnolipid biosurfactant production

¤ Our team develops novel strategies for cost-efficient rhamnolipid production

¤ We strive to establish new, creative applications for rhamnolipids

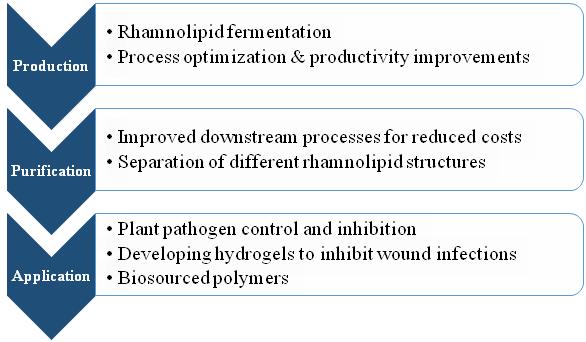

Our lab has been conducting research on production, purification, and applications of rhamnolipids for more than a decade. We have in-depth experience with rhamnolipid production and have developed advanced fermentation technologies for both upstream and downstream processing. We have also been using rhamnolipid as a platform molecule in custom bio-polymer applications (such as polyurethanes, wound dressings, coatings, etc.)

The “big picture” for the rhamnolipid project

1. Rhamnolipids are high-value effective biosurfactants that can be produced by Pseudomonas aeruginosa from low-cost carbon sources.

2. These biosurfactants are recognized for their immense potential in bioremediation, enhanced oil recovery, cosmetic, and pesticide industries.

3. Large-scale production of rhamnolipids involves many challenges due to the foaming nature of the culture broth and the complex metabolic regulatory mechanisms.

4. To reduce foaming, the aeration rate during fermentation needs to be lowered. The lower oxygen supply then compromises cell viability due to poor respiration conditions and ultimately decreases the rhamnolipid production.

Our lab has the equipment and facilities to simultaneously research multiple aspects rhamnolipid production and application. We have six New Brunswick Scientific Bioflo 110 fermentors for studying bioprocess methods. Furthermore, we have various analysis equipment including HPLC, mass spectroscopy, and light scattering instruments for rhamnolipid characterization. Moreover, we have achieved high-purity rhamnolipid by applying various bulk scale purification techniques. Occasionally, different rhamnolipid chemical structures are separated by applying one or more thin film chromatography and/or column chromatography techniques.

We can completely eliminate the severe foaming associated aerobic conditions by using denitrifying fermentation conditions to reduce foaming. Utilization of P. aeruginosa’s nitrate respiration and avoids foaming problems associated with air bubbling. However, nitrate requires tighter process control and management for successfully, high yield production.

The current focus of our team is finding innovative methods for effective rhamnolipid based plant pathogen treatment. This research will benefit agriculture industries and the environment by replacing synthetic chemicals with a safe and biodegradable soap. This work also encompasses advanced production techniques to further improve yield and drive down manufacturing costs.

Additionally, we have been developing hydrogels for wound dressings. The primary objective is controlling the release of rhamnolipid to inhibit the microbial infection during the wound healing process. This work combines a complex mixture of transport phenomena and reaction kinetics to describe the oxygen movement and rhamnolipid release.

Example of Purified Rhamnolipid |  Rhamnolipid separation using chromatography |  Testing rhamnolipids to inhibit plant pathogen growth |

Publications:

- Rhamnolipids as Platform Molecules for Production of Potential Anti-zoospore Agrochemicals (Shida Miao, Soroosh Soltani Dashtbozorg, Nicholas V. Callow, and Lu-Kwang Ju) J. Agric. Food Chem., 63(13), 3367–3376 (2015). DOI Link

- Ethylation of Di-rhamnolipids: A Green Route to Produce Novel Sugar Fatty Acid Nonionic Surfactants. (S Miao, N Callow, SS Dashtbozorg, JL Salager, LK Ju) Journal of Surfactants and Detergents 17 (6), 1069-1080 (2015). Article Link

- Ethyl rhamnolipids as a renewable source to produce biopolyurethanes. (S. Miao, N. V. Callow, L.-K. Ju) European Journal of Lipid Science and Technology 117(2), 156-160 (2014). Article Link

- Cells were a more important foaming factor than free rhamnolipids in fermentation of Pseudomonas aeruginosa E03-40 for high rhamnolipid production. (M. Sodagari, L.-K. Ju) Journal of Surfactants and Detergents 17, 573-582 (2014). Article Link

- Continuous rhamnolipid production by denitrifying cells using hollow fiber reactor. (N. M Pinzon, A. G. Cook, L.-K. Ju) Biotechnology Progress 29(2), 352-358 (2013). Article Link

- Improved detection of rhamnolipid production using agar plates containing methylene blue and cetyl trimethylammonium bromide. (Pinzon, Neissa M.; Ju, Lu-Kwang. ) Biotechnology Letters 31(10), 1583-1588 (2009). Article Link

- Analysis of rhamnolipid biosurfactant by methylene blue complexation. (N. M Pinzon and L.-K. Ju) Applied Microbiology and Biotechnology 82(5), 975-978 (2009). Article Link

- Advances in Bioprocess Development of Rhamnolipid and Sophorolipid Production. (N. M. Pinzon, Q. Zhang, S. Koganti, and L.-K. Ju) Book Chapter in Bio-Based Surfactants, D. G Hayes, D. Solaiman, R. Ashby, and D. Kitamono (Eds.), AOCS Press (2009).

- Monitoring microaerobic denitrification of Pseudomonas aeruginosa by online NAD(P)H fluorescence. (L.-K. Ju, F. Chen, and Q. Xia) Journal of Industrial Microbiology and Biotechnology 32, 622-628 (2005). Article Link

- Correlation of denitrification-accepted fraction of electrons with NAD(P)H fluorescence for Pseudomonas aeruginosa performing simultaneous denitrification and respiration at extremely low dissolved oxygen conditions. (F. Chen, Q. Xia and L.-K. Ju) Biotechnology Progress20(5), 1593-1598 (2004). Article Link

- Modeling rhl quorum-sensing regulation on rhamnolipid production by Pseudomonas aeruginosa. (F. Chen, C.-C. Chen, L. Riadi and L.-K. Ju) Biotechnology Progress 20(5), 1325-1331 (2004). Article Link

- Aerobic denitrification of Pseudomonas aeruginosa monitored by online NAD(P)H fluorescence. (F. Chen, Q. Xia and L.-K. Ju) Applied and Environmental Microbiology 69(11), 6715-6722 (2003). Article Link

- Rhamnolipid production by Pseudomonas aeruginosa under denitrification: Effects of limiting nutrients and carbon substrates. (C. Chayabutra, J. Wu, and L.-K. Ju) Biotechnology and Bioengineering 72, 25-33 (2001). Article Link

- Monitoring of denitrification by Pseudomonas aeruginosa using on-line fluorescence technique. (L.-K. Ju and H. K. Trivedi) Biotechnology Techniques, 6, 549 (1992). Article Link