Hello everyone,

With mid-semester upon us, this has to be the busiest time our makerspace has yet experienced. For the past week or so, all three printers are under continual use, mostly from the engineering students printing motor parts, the RC Club printing airplane parts, student printing their own things, etc. All three are humming along with minor problems here and there. I didn’t expect this, but students now ask if we will buy more 3D printers, given they have to wait and take turns using them.

Friday before last, Kevin Platz and kids from the Orrville Boys & Girls club and the mayor of Orrville arrived to receive the grant check from an AT&T representative for the vinyl cutter. It is quite an honor to have a collaboration with OBAGC, sharing equipment, resources, Wayne personnel, and teaching kids skills that could one day lead to careers. It was an exciting time and the kids are still fascinated with our 3D printers.

Representatives from Orrville City Schools also stopped by last week to talk about the Wayne makerspace and the possibility of future STEM related collaborative efforts with Wayne College. In the corner of the photo, Dusty pauses teaching a local business how to design in CAD during the meeting:

Students and staff are excited about the vinyl cutter. It is quite easy to use; we recently posted easy-to-follow instructions on the wall above it. There was quite a party last Friday as students cut logos and graphics for their cell phones, decorating the lab with Aperture Science logos, and more.

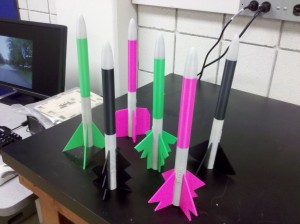

Speaking of the Orrville Boys and Girls Club, we have been busy teaching the kids how to design model rockets using SolidWorks, a powerful yet easy-to-use CAD program. The kids designed body tubes, body extensions, and fins; they will soon use the 3D scanner to replicate nosecones in a couple of weeks. Their rockets are certainly creative! We hope to actually launch them using custom rocket engines and fuel designed by Dusty, our resident chemical engineer:

Earlier this summer, Paul Locher from the Daily Record brought-in a plastic window clip that frequently breaks apart while removing his home’s wooden window framework for cleaning. Dusty designed and printed replacement clips, but they did not fit since we did not have the wooden frame to test them with. Paul recently brought in a frame, Dusty tweaked the design, and now we have perfectly fitting window clips! The new clips are stronger and less likely to break than the original design. Here are the iterations from the original clip (left) to the latest redesign (right):

Next week, students are testing their motor designs for a final grade and testing their latest LEGO robot designs. It’s amazing to see all of the energy in there.

President Obama is seriously pushing digital fabrication to the nation’s youth. Earlier this year was a Maker Faire hosted at the White House, this December is a competition for 3D printed ornaments:

Robots for consumer use is all the rage this year. But instead of buying robots at the store, why not make your own? See how this UK based Maker Club brought together a band of makers to create robots for the home and educational robots as learning systems for schools:

http://www.gizmag.com/maker-club-robotics-3d-printing/34577/

Until next week,

Tom