With finals being underway this week, students use the 3D Lab to complete homework, tutor each other, study for finals, 3D print items of interest, and just “hang-out”. It is a wonderful place for collaboration for disciplines of many types, not just engineering.

Even as the semester draws to a close, plans are already in the works for an exciting summer, especially for the Orrville Boys and Girls Club. We are organizing a summer camp where kids will build model R/C airplanes from scratch. This project involves most technology in the room, including laser cutting, 3D printing, electronics, and vinyl cutting. Stay tuned for more information about this camp.

Earlier this semester, our history professor wanted to create t-shirts to promote the college’s student travel group. He provided Ifrah with a high-resolution photo of the group’s logo. She traced the logo with the vinyl cutter software, touched up and improved the accompanying graphics, then cut the logo onto thermal-sensitive vinyl. The heat press (provided by the Orrville Boys and Girls Club) transferred the image onto a t-shirt with excellent results. Thanks, Ifrah!

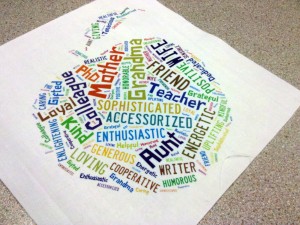

Many faculty and staff contributed to Sue Horn’s retirement quilt. Some embroidered their own squares while others enlisted Word Processing and the 3D Lab! Morgan heat pressed vinyl designs onto squares which turned out beautifully. Carolyn laser printed color designs onto iron-on transfer sheets which bonded to the quilt squares using the heat press. We are discovering all sorts of new projects for these machines.

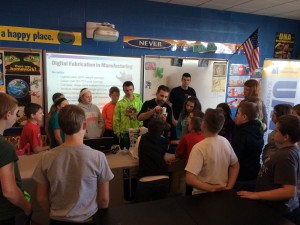

Last week, Kevin Engle made a connection with Green Middle School in Smithville. The science instructor wished to demonstrate 3D printing and careers in engineering to her students. Nathan and I explained the technology to four classes of interested students. Even though we had 40 minutes per class, it was barely enough time to cover the content and answer all of their questions. Handing out candy for correct answers to our questions helped motivation, too. 🙂

Last but not least, one of our staff wanted to create a kangaroo cookie cutter to promote an event at the college. Morgan traced a design from paper to the computer using a graphics tablet. Anthony then converted this 2D design to a 3D shape using CAD software. The resulting cookie cutter was printed on our portable 3D printer (provided by the Romich Foundation). A local bakery baked and frosted the cookies, which are shown below. This was truly a group effort (and a tasty one)!

Work has resumed with the laser engraver installation, just in-time for the summer camp project. We hope to have this machine up-and-running in just a few weeks.

3D printing is an essential tool in the biomedical field. See how a DNA-scanning microscope is made possible with 3D printed parts:

http://www.gizmag.com/smartphone-dna-scanning-microscope/37288

Instead of glasses, contacts, and Lasik, how about a replacement eye? See how an Italian company hope to market synthetic eyeballs with bio based 3D printing:

http://www.gizmag.com/mhox-3d-bioprinted-synthetic-eye-concept/37113

Stay tuned next week as we report more on exciting developments in the 3D Lab.

Tom