Hello everyone,

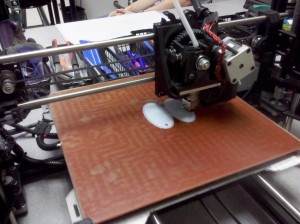

Being Spring Break this week at Wayne College, the building has been quiet with students mostly staying home. But some still wander into the 3D Lab to work on projects, use the 3D printers, and socialize a bit. It was a good time to do some “spring cleaning” as the lab becomes quite messy from the constant activity.

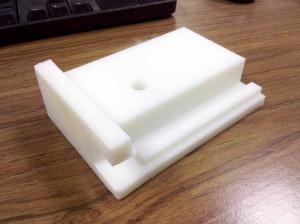

A couple of months ago, we met Kelly, one of our community members, at an business event at the Buckeye Event Center. Being an an avid woodworker, he uses his machines heavily. Kelly wondered if the 3D Lab could replace a broken accessory for his router table, a bracket that holds the router guide in-place. We used the free AutoDesk 123D Design program to easily draw and replicate the broken piece.

To fabricate the part as strongly as possible, we printed it with 50% HIPS plastic, taking about nine hours to print.

If you haven’t tried the 123D suite of free programs, run over to www.123dapp.com! These high-quality 3D applications are amazing, including 3D scanning, CAD design, 3D sculpting, and cleaning up 3D items. The creative possiblities are truly endless. An excellent book that introduces these programs is “3D CAD with AutoDesk 123D”.

Kelly reported that the replacement router bracket fits perfectly onto his router table, so we have another satisfied customer!

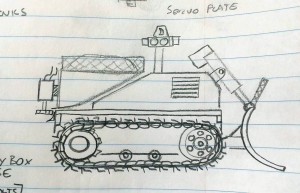

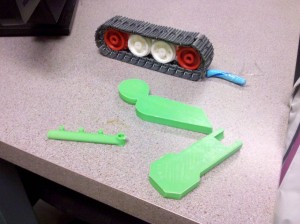

Don, a University of Akron student partly responsible for designing automatic brake lights for bicycles (he technically calls it a “velocity dependent slow moving vehicle bicycle tail-light system”), is concocting a new project: an autonomous snow plow. This is a design project for his Robotics class at the Akron campus. The plow will manage snow around the home and dispense anti-icers to reduce the risk of falling or heart attacks for elderly or disabled people in winter.

Currently, Don is building the track system using premanufactured tracks attached to 3D printed wheels. All of this is a small-scale prototype, of course. I wouldn’t want to stand in the way of a full-size version of this machine running about!

The makerspace at the Schantz Organ Company is gaining momentum. In a short period of time, they formed connections with regional businesses, organizations, and schools in this new era of digital fabrication. Community members have used the Schantz facility to fabricate corn hole boards using a CNC router, welded and bent metal shapes to form outdoor drink holders, and other projects.

Wayne College is proud to be a part of this movement. A couple of weekends ago, the 3D Lab hosted a “CAD design and 3D printing workshop” where community members designed and printed personalized keychains. We accomplished all of this in a mere three hours, with some folks never using CAD design software before. Everyone had a wonderful time.

Stay tuned as the semester fires back up next week with students continuing all sorts of interesting projects!

Lost your hair? This Italian studio can 3D print a replacement so realistic even you’ll be fooled:

http://3dprint.com/117092/cesare-ragazzi-laboratories

See how this college student 3D printed his own braces:

http://money.cnn.com/2016/03/16/technology/homemade-invisalign/index.html

Combine a Raspberry Pi credit card computer with 3D printing to create your own retro Game Boy gaming machine:

http://www.thingiverse.com/thing:807591

Until next week,

Tom