Hello everyone,

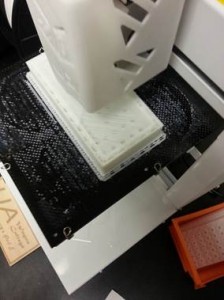

We’ve been busy this week at the Wayne College Maker Space. We printed 3D models for two local companies. The first was a cup to hold liquid resin to see if PLA plastic can hold up to its heat. The second were a couple of objects to see how a 3D printer could reproduce them.

On the local front, students Dusty and Josh are creating new CAD designs. In the Chemistry Lab, there are glass implements that have a difficult time being dried out due to their shape. Dusty created an air distributor that evenly applies airflow to the glass implements:

What was amazing about this print is that we printed an object that was hollow in the middle and enclosed on all six sides. Normally, the “roof” of the object has to be supported by temporary plastic underneath (called “supports”). But because the object was enclosed, we could not use supports because there would be no way to remove them afterward.

We used the portable 3D printer for this task. When the printer began printing the “roof”, it drew long strands of plastic in mid-air, connecting the sides. This seemed impossible, but it worked!

Lastly, Josh designed a phone stand for large, wide-format smart phones. He is getting really good at attractive designs in Creo:

In other news, HP made an announced six months ago that they plan to enter the consumer 3D printer market. They realize that 3D printers are becoming mainstream, so they want to be ready with their own product:

http://www.computerworld.com/s/article/9247078/HP_has_solved_two_big_problems_with_3D_printing

In the medical world, 3D printer technology was used to save a baby’s life by keeping her brochi open due to a birth defect:

http://hackaday.com/2014/04/02/3d-printed-split-saves-babys-life

Stay tuned for new things happening at the Wayne College Maker Space next week!

Tom