Hello everyone,

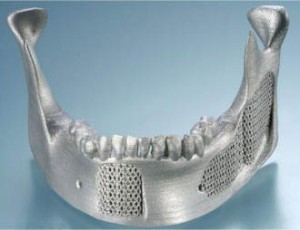

Summer session hasn’t slowed down the activity at the Wayne College Makerspace. Of particular note was a field trip to America Makes, a national 3D printing research center in Youngstown, Ohio.

America Makes fosters engagements with businesses, academia, non-profit organizations, and individuals. Members present challenges, projects, and direction in which AM researches, completes, and documents. For instance, if NASA has a particular project that involves 3D printing, AM researches this project for them. The University of Akron is a proud member of America Makes as well.

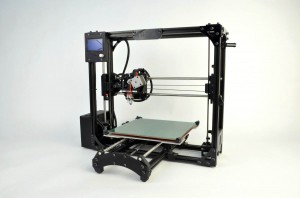

The equipment at this facility is impressive. They have almost a dozen consumer-level 3D printers. They also have a StrataSys Fortus, a large refrigerator-style 3D printer for high quality prints. Check out all of the different technologies that they research!

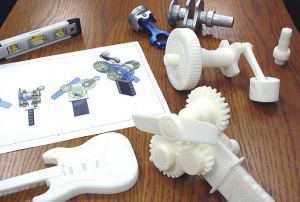

On the home front, Dusty is coming along with the suspension system for a radio controlled car. Don’t ask me how it works; I haven’t a clue. 🙂 It is amazing that he is designing this from scratch.

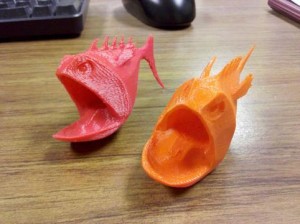

We had a difficult print request, a figure of a fish where there was no flat area to sit on the print bed. Furthermore, there were hollowed out areas that would be difficult to print, as temporary plastic is needed to fill the cavity.

For this job, we used white, dissolvable filament. In areas that needed to be filled to support cavities and strange angles, the dissolvable filament was used instead of regular plastic. After the part printed, we soaked it in limonene to dissolve away the unneeded plastic. Below, the red object in the middle is the fish, the white plastic coming out of its mouth is the dissolvable filament:

And the finished product:

If you wish to have anything printed from www.thingiverse.com, feel free to submit your request via Service Request (the yellow smiley)! We are always up for new challenges.

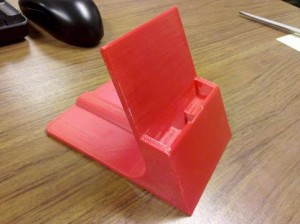

We also printed another attractive phone stand, this time for Jackie.

Another bit of exciting news is that through a collaboration with the Orrville Boys and Girls Club, we will have access to a 3D scanner! This way objects are photographed then immediately 3D printed. It can also be used as a template to reproduce an object in CAD, quickening the process.

Stay tuned as we begin to explore this new technology!

Check-out this home-built 3D printer that uses concrete, not plastic. This man is building a playhouse castle for this kids using additive manufacturing, right within his home! A fascinating video is included, too:

Check-out this home-built 3D printer that uses concrete, not plastic. This man is building a playhouse castle for this kids using additive manufacturing, right within his home! A fascinating video is included, too:

http://hackaday.com/2014/05/29/man-builds-concrete-3d-printer-in-his-garage

Until next week,

Tom