Hello everyone,

The summer has not slowed down activities of the Wayne College makerspace. Thanks to Dean Deckler, the Maintanance Department, and Technical Support Services, we now have a full fledged makerspace room! Please visit A-121 (outside the previous location) to check things out and receive a tour. We have plenty of room for our existing 3D printers, scanner, extruder, and expansion for future equipment. There is a sink for chemical cleanup and a fan for future machines that need an exhaust. And there is an eight-computer class area for offering workshops. We have big plans for this room.

Dusty’s R/C car design (based on our engineering classes’ LEGO Mindstorms hardware) is coming along well. He intends to build the car completely from 3D printed plastic. His current project are universal joints used to turn the wheels. It is a multi-part, multi printed assembly that works beautifully!

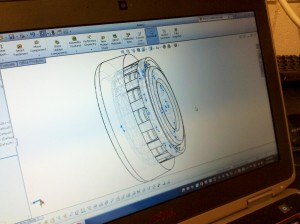

Dean Deckler challenged Dusty to create a thrust bearing, providing him with a metal model as a reference. The on-screen design that he made is a work of art, though we have not printed it yet:

3D printed parts made with ABS plastic may have a rough look, especially if they are smoothed with sandpaper. One trick we learned is exposing the part to heated acetone vapor. The vapor slightly melts the plastic skin of the object, resulting in a glossy finish. Ask Michelle Turner to show her Darth Vader pen cup to you for an example.

We recently tried to acetone-smooth a coffee cup lid that was 3D printed. However, we exposed the vapor for too long, causing the plastic to boil and bubble. So it is back to the drawing board for our acetone procedure:

Stay tuned as we report exciting development in-store for the new makerspace lab!

There are many companies producing 3D printers, though have disparate software that makes using multiple printers difficult. AutoDesk (makers of AutoCAD) is releasing a software platform called Spark that can be used to support any 3D printer. They are also going to sell their own 3D printer hardware:

http://arstechnica.com/gadgets/2014/05/autodesk-introduces-spark-an-open-3d-printing-platform

3D printers are making their mark in space! Not only does NASA have a 3D printer on the International Space Station for printing on-demand parts, SpaceX is using them to print thrusters for their SuperDraco spacecraft:

http://www.gizmag.com/superdraco-test/32292/

For past e-mail postings, check-out our blog at:

http://blogs.uakron.edu/waynec3/

Tom