Hello everyone,

The rain has (mostly) subsided since the start of summer last week. The sunny heat almost hits like a wall when leaving the building. For a cool place to work on your projects (pun intended), come visit the 3D Lab! We’ve had a steady stream of visitors each day since the end of semester, so we’re happy to help make your ideas possible, too.

We are particularly pleased with a recent visit by members of the Apple Creek Historical Society. Their intention is to create a makerspace for the community to use, along with providing a variety of programs on projects that can be made. They are collecting a variety of woodworking equipment and tools as donations, both financial and/or equipment, become available. Just recently their vision has expanded to include a laser cutter, CNC router, and providing instruction on how to make a 3D printer.

ACHS hopes to get the program put together and on its feet by Fall. If you wish to know more, please contact Gary Rogers, 330-201-1745 (call or text).

The vinyl cutter in the 3D Lab is a popular machine by many. It is a 2D machine, meaning that designs are flat, created with simple text and graphics. Both are converted to “vector” format, which are curves and lines that a blade follows to cut your design in vinyl. Vinyl cutters are great for decals and custom stickers, but even more useful for clothing! Heat transfer vinyl can be pressed into cloth using a heat press, which the 3D Lab also has.

Earlier this spring, students and teachers made custom t-shirts using a vinyl cutter with amazing success. Karen Sieffert made her own tie-dye shirts for a church summer camp, then heat pressed vinyl lettering and graphics in white vinyl on top. The result is quite beautiful. Karen made a lot of these shirts and is an expert vinyl cutter now.

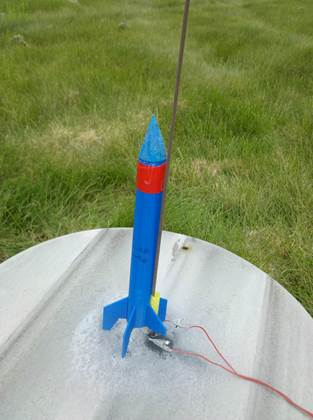

This past Spring semester, engineering students in the Dynamics class built and flew model rockets, many of which were 3D printed in our lab. Mark Schworm designed a complex rocket that had wings embedded in the rocket, popping out to allow the rocket to “float” back down to Earth! The first launch of Mark’s rocket didn’t go so well, but the second attempt was stellar! His design worked perfectly.

Other students built rockets with custom fins and nosecones, each going through mathematical studies to determine proper center-of-pressure, center-of-gravity, and wind tunnel measurements. All of the rockets flew well this semester because of this preplanning.

The 3D Lab is open over the summer, so feel free to stop in! Our hours of operation are posted here.

Stay tuned next week as we introduce interesting folks who participated in this year’s Maker Faire!

Baldness breakthrough uses 3D-printed “hair farms” to grow new hair follicles

https://newatlas.com/3d-printed-hair-follicles-restoration-surgery/60299

Michelin and GM Unveil 3D Printed Puncture Proof Tire Prototype Called Uptis

https://all3dp.com/4/michelin-and-gm-unveil-3d-printed-puncture-proof-tire-prototype-called-uptis

Summer is perfect for a bicycle bubble machine! https://all3dp.com/1/project-bicycle-bubble-machine

Or make 3D printed custom bubble wands

https://www.instructables.com/id/Custom-Bubble-Wand

Thanks for another incredible Maker Faire 2019! You can find information about past participants here.

Don’t miss the next Maker Monday on Monday, July 15th at 7:00 p.m. at the Schantz Makerspace in Wooster. Find out more at www.schantzmakerspace.com

We offer a free “listserv” that allows to you ask questions to members in the makerspace. It’s great for sharing ideas, forming friendships, and helping & advising each other. To join, send an email to listserv@lists.uakron.edu with “SUBSCRIBE MAKERSPACE-GROUP” in the subject line.