Hello everyone,

The Spring semester is flying by with less than two months before its end. Despite the pandemic restricting gatherings in the 3D Lab, there is a constant stream of community requests to make things such as laser engraved/cut items, 3D printed objects, posters, and vinyl decals. Community groups like Schantz Makerspace plans to make a comeback this Spring, looking to host their first 2021 monthly meeting in the next month or two. Bringing people together again is what makerspace is all about, to share ideas, build and fix things, and learn from and fellowship with each other.

While the 3D Lab continues to be open to students yet closed to the public out of COVID precaution, our staff has plenty of time to keep the equipment in good order. The controller boards failed on our full-color printer (courtesy of the Romich Foundation) and one of our large-format Taz printers (courtesy of the Wayne County Community Foundation). Both boards were replaced and the printers are back in operation. 3D printers are quite resilient machines overall, despite the numerous moving parts, hot temperature, and for operating many hours on a single job. We are thankful to offer a variety of printers as machines are in various states of operation.

The 3D Lab continues to provide free services for the community with our digital fabrication equipment and materials. Feel free to contact us below if you have a project that we can assist with! Click here for a complete list of equipment.

Smithville is home of the Mishler Weaving Mill. Founded in 1887, John Sr. established a weaving business making rugs for customers on a loom that his friend Matthias Gerber had helped him build.

The Mishler Mill made cheesecloth and press cloth for use in cider, juice, and wine making. Back in the day, it supplied Kraft, Welches, and other national brands, as well as other lesser known companies. Current FDA rules no longer allow the use of reusable cotton fabric for food production. This is what shut-down the commercial use of the mill. Until then, it was able to produce fabric from untreated and unbleached cotton for commercial use.

One of these antique looms was malfunctioning, so a member of our local maker community set-out to fix it! The mechanized loom Barry was working on is similar to those in this video. Mishler’s looms also use the original line shafts to operate, similar to the National Parks Service weaving mill, but on a smaller scale (only three mechanized looms and one warping reel).

The issue with this particular loom was the picking mechanism. It wasn’t shooting the shuttle across well on one side. This loom is a bit more complicated than most looms of the era: it not only lifts the threads up-and-down, but moves them side-to-side to put an extra twist on the warp threads, between each shuttle shot. This creates an open weave construction for their dishcloths.

Many thanks to Robin for providing this story! If you wish to know more about the Mishler Weaving Mill, please call 330-669-9308 or email shsmill@sssnet.com.

Interesting in getting into knitting? Consider these inexpensive circular knitting machines for making winter hats, scarves, socks, and more.

Back in the 3D Lab, a few years ago the lab was provided with two large-format Lulzbot Taz 3D printers as mentioned above. These heavy-duty printers fabricate objects almost 10 inches tall and can print with unusual materials like rubber and nylon. They have been a boon to our students and community members alike, especially for printing tall model rocket parts.

Parts meant for outdoor use are printed in ABS plastic which does not soften in the heat of the sun. However, printing with ABS is difficult; the plastic shrinks too fast while cooling, resulting in cracks. To reduce this problem, lab staff Nathan built a box to keep the printer warm from its own heat.

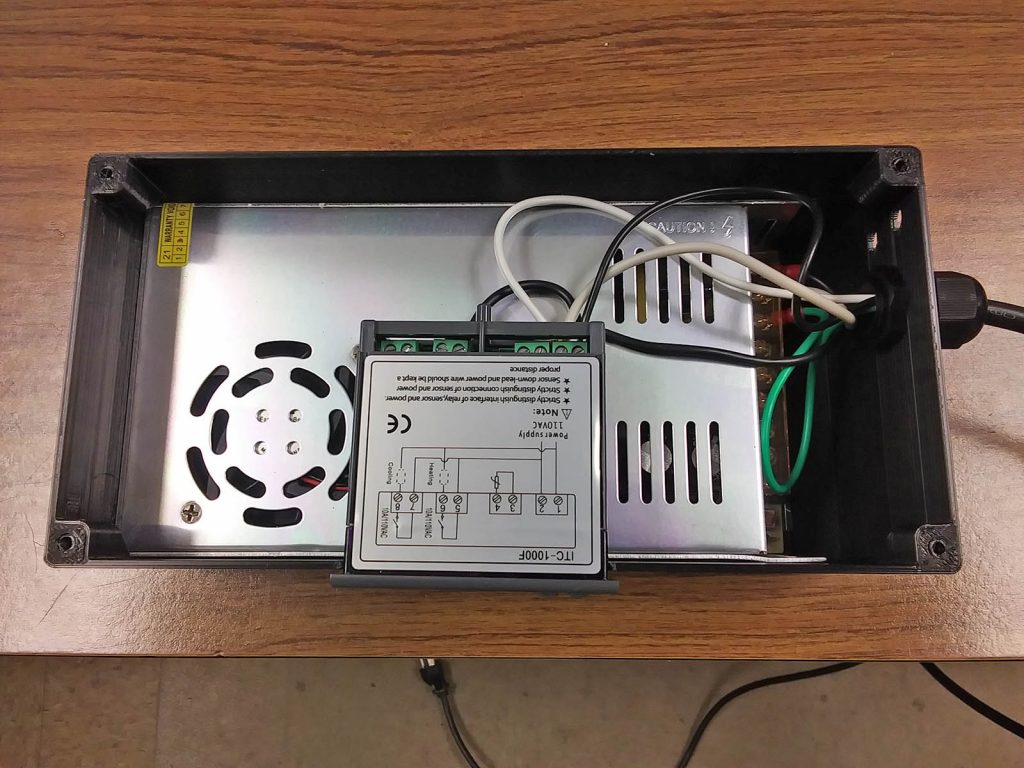

This retained some heat, but cracking still formed in large printed objects. Because “makers gonna make”, we invented a heating system involving a 300W commercial heating element, 24V power supply, and a temperature controller.

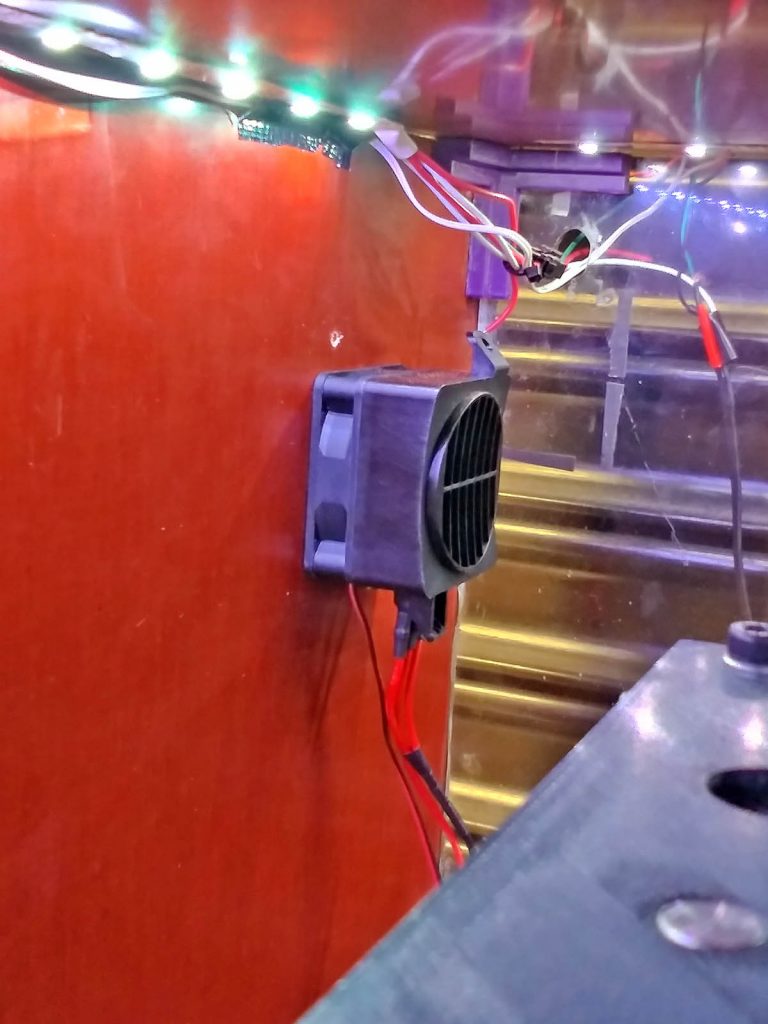

The challenge is to keep the printer toasty warm inside and prevent the internal controller board from overheating. To solve this problem, we printed a custom air duct that allows cool air to enter the controller box and exhaust it back outside, not affecting the enclosure’s heated environment.

Because the enclosure is so large, the heating system can almost reach 40 degrees Celsius, though our target temperate is 50-70. It is certainly an improvement, but not perfect. The next plan is to add insulation to reduce heat loss. We’ll report more on this progress soon!

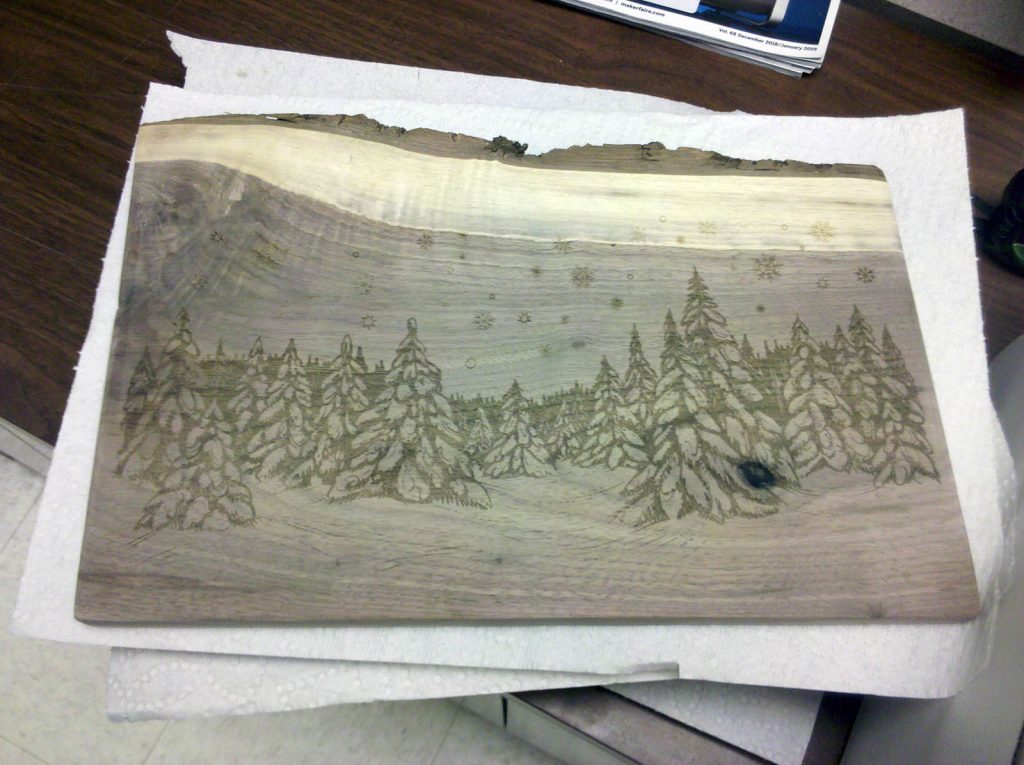

The 3D lab is a great place to make homemade, personalized gifts. Companies such as P. Graham Dunn, Durbin Floors, Jay’s Glass, The Wooster Glass Company, The Romich Foundation, and others donate materials that are freely available to students and community members. Our motive is that the gift makers learn new and useful skills in the process! Check-out this wintery scene that was engraved onto a plank taken from the family’s own property, a memorable heirloom:

As mentioned above, the 3D Lab continues to provide free services for the community with our digital fabrication equipment and materials. Feel free to contact us below if you have a project that we can assist with!

Stay tuned later this month as we introduce more interesting folks who participated in the latest Maker Faire!

Until then,

Tom

With warmer weather comes a full-size 3D printed speedboat!

https://hackaday.com/2021/01/30/3d-printing-a-full-scale-fiberglass-speedboat

3D Printing Can Keep Aging Air Force Aircraft Flying

https://www.wired.com/story/air-force-3d-printing-parts-manufacturing-olympics

3D printing photos is slow but awesome

https://hackaday.com/2019/03/05/3d-printing-photos-is-slow-but-awesome

Maker Faire Wayne County 2021 is canceled out of COVID19 precautions. Still wanted to attend a maker faire this year? Mark your calendar for Virtual Maker Faire Lynchburg this coming weekend!

Maker Monday is postponed out of COVID19 precautions. Please check www.schantzmakerspace.com for future meeting dates, workshops, and activities as some dates have changed.

We offer a free “listserv” that allows to you ask questions to members in the makerspace. It’s great for sharing ideas, forming friendships, and helping & advising each other. To join, send an email to listserv@lists.uakron.edu with “SUBSCRIBE MAKERSPACE-GROUP” in the subject line.