Hello everyone,

As we gear-up for printing model rocket designs for the engineering classes next week, the 3D printers have been busy. Dusty is in the process of designing a “parts rinser” based on the Pythagorean Cup that we printed for Dr. Vierheller. There are instruments in the Chemistry Lab that are difficult to clean; they must be rinsed in a solution 30 times. To simply this procedure, this idea was created:

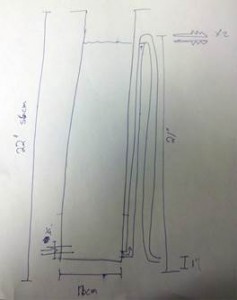

Basically, as solution enters a container in the lower-left corner, the container slows fills. A vertical tube on the right side of the container also fills. When the solution reaches the top, then container will automatically drain all of its fluid through the vertical tubing. The container then fills again, etc.

A device like this could cost $400, but Dusty is creating his own design from scratch. It will be a tall object (21”), so we are printing it in 6” sections:

Stay tuned as we finish this project in the coming week!

We also finished printing another adjustable wrench, a seven-piece design that requires fitting and gluing. We plan to print a different design that prints the entire wrench, self assembled, in one pass:

In 3D printing news, a woman in the Netherlands had a condition where her skull is slowly thickening, causing blindness and eventually death. Instead of sculpting a crude replacement skull using medical cement on the operating table, a company called Anatomics made a perfect replacement skull using 3D printing. It’s been three months since the replacement; now the woman can see and her condition is improving!

Stay tuned for further happenings at the Wayne College Makerspace!

Tom